Create product masters with variants

Differing from product attributes, product dimensions let you track their values in all major processes, such as for cost, inventory, and analysis purposes. Product attributes can be associated with products and product masters, whereas product dimensions can only be used together with product masters (except for masters that are set up by using the Constraint-based configuration option). The reason is because they make up the uniqueness of a product master's variations.

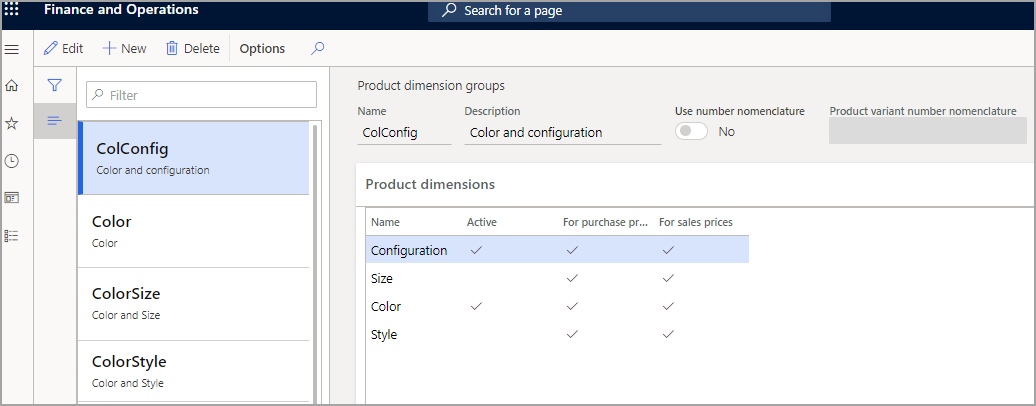

You can determine which product dimensions are mandatory for a given product master by selecting the appropriate product dimension group when you create the product master.

Go to Product information management > Setup > Dimension and variant groups > Product dimension groups page to create product dimension groups.

Because the product dimensions provide the uniqueness of a variation, the following rules apply:

- The dimension must be specified when product transactions are created, for example when a purchase or sales order line is created.

- The specified dimension applies only to the product transaction. You can't fully or partly change the dimension value for the related inventory transactions on physical issue or receipt.

- Products are always reserved for each dimension. You can't reserve products for dimension values other than those that are specified on the action product transaction.

Model configurable products

By going to product setup at Product information management > Products > Released products > New, you can model configurable products. When you work with product masters, make sure that you define how variations of a master are created. Frequently, many mandatory attributes must be specified to create a new variation.

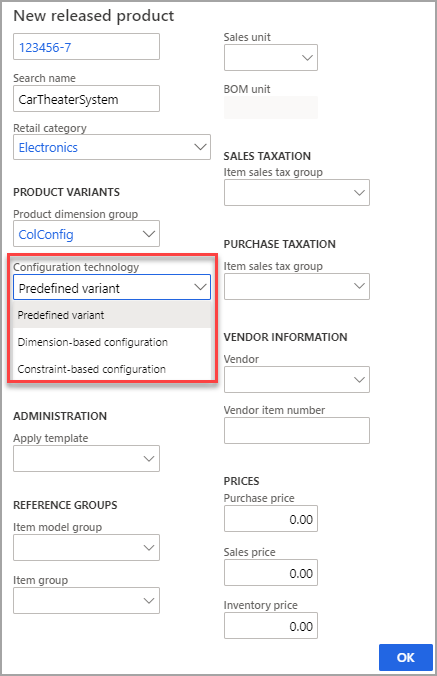

The configuration technology that is set up on its product master controls how such a variant is modeled:

Predefined variant - This type enables the product to be modeled based on the product dimensions, color, configuration, and size. This option is the only one that can be set up directly with product variants. Any combination of the product dimensions is allowed.

Dimension-based configuration - A configuration technology that is used to create product variants by selecting values for product dimensions. Any combination of the product dimensions is permitted.

Constraint-based configuration - This type enables products to be used in the Product configurator. To select this type, the product dimension group must have Configuration enabled, and no other product dimensions can be enabled.

Define product master and predefined product variants

When you use the Predefined variant configuration technology, the variant uniqueness is based on the combinations of one or more applied product dimensions.

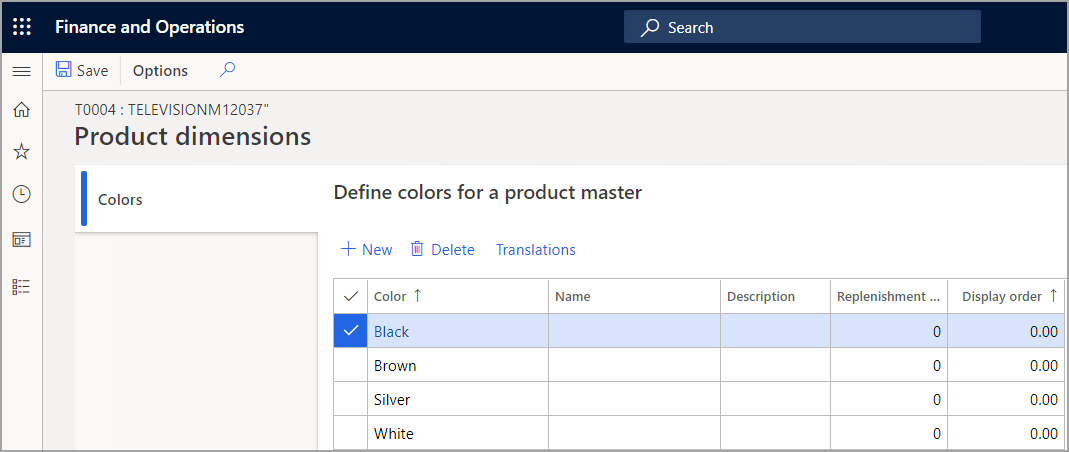

For example, the USMF company has different colors of televisions. Each color is a product variant that contains the details about that product. The product master contains default values for all models of the television.

In USMF, you can create a Released product as either product or product master and then set up predefined variants.

The dimension group that you attach to the product master determines which product dimensions are mandatory when you define its product variant(s). When you select a product dimension group and create the first product variant or assigned dimension values, it can't be changed.

Scenario

The sales manager at USMF evaluated the latest sales forecast numbers for the new 60-inch LCD television and has received various feedback. As a result, the sales manager has concluded that the LCD televisions should be available in multiple colors.

The sales manager confers with the product designer and production manager, and they agree that the new colors will be black and silver. Furthermore, they agree that the cost for the black and silver televisions will be the same.

The product designer wants to make sure that color is a mandatory product characteristic when the sales representative sells the product. Additionally, the color offering must be restricted to the agreed-on list.

Product master and dimension-based configured product variants

Similar to the Predefined variants configuration technology, the Dimension-based configuration option requires you to use one or more product dimensions. The advantage of the dimension-based configuration is that you can create configuration rules and maintain configurations of bill of materials to make it easier for sales people to set up the BOM product in the sales order.

Dimension-based product configuration

Dimension-based product configuration represents a simple solution for creating many product variants from a single product master and its bill of materials.

Dimension-based product configuration is based on the following key concepts:

- Product masters

- Configuration product dimension

- Configuration groups

- Bill of materials (BOM)

- Configuration route

- Configuration rules

Product masters

A product master is the starting point for any product configuration process. For the dimension-based product configuration, you need a product master with this configuration technology and a product dimension group that includes the configuration product dimension.

Configuration product dimension

The configuration product dimension is used to identify the product variants for a product master with the dimension-based configuration technology. The configuration dimension value is entered by the user and should help to identify the individual product variants.

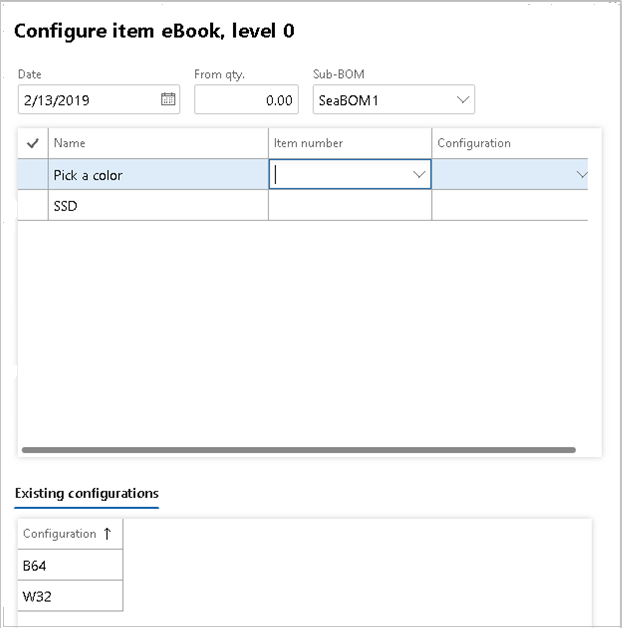

Configuration groups

Configuration groups are defined in a central repository and can be used for all dimension-based product configuration models. Configuration groups are associated with the individual BOM lines and hold together a group of lines that are mutually exclusive. Essentially, you can select only one line in a group for a single product variant.

Bill of materials

Bill of materials (BOM) represents the building blocks for a dimension-based product configuration. It must include all different products that can be used in any product variant. Each line in the BOM can reference a configuration group. If a line doesn't reference a configuration group, it will be included in all product variants.

Configuration route

The configuration route determines the sequence of the configuration groups as they will be displayed to the user during the product configuration process.

Configuration rules

The configuration rules represent a mechanism for ensuring that a product that is included in one configuration group in a BOM enforces an inclusion or an exclusion of a product in a different configuration group in the same BOM.

For dimension-based configured products, the selection and creation of the variant of a product master is determined by the choice that the sales order taker has recorded, based on the defined configuration rule.

Scenario

The USMF company has many home theater systems that are produced in the same manner. These systems offer various features that are interchangeable, such as different color and size DVD players and subwoofer models. When the order processors use dimension configurations, they only have to set up one product for the DVD player, and they can still provide the available combinations of DVD players and subwoofers that the customers want.

Product configuration

As many products have become commodities (such as cars, televisions, household appliances, and more), the need to differentiate them has arisen. The immediate response of manufacturers to this challenge has been to create variants of each product so that customers have more alternatives. This strategy has led to increased forecast challenges and to an increase in inventory cost and unsold products that become obsolete.

By adopting a configure-to-order philosophy, manufacturers can meet customer demand for unique products while reducing or eliminating obsolete inventory items. When a manufacture-to-stock philosophy is shifted to a configure-to-order philosophy, one immediate challenge is that the need for short lead times must be balanced against low inventory levels.

The key to success is to carefully analyze the product portfolio and to look for patterns in product features and processes. The goal is to identify generic components that can be manufactured by the same equipment and used in all variants.

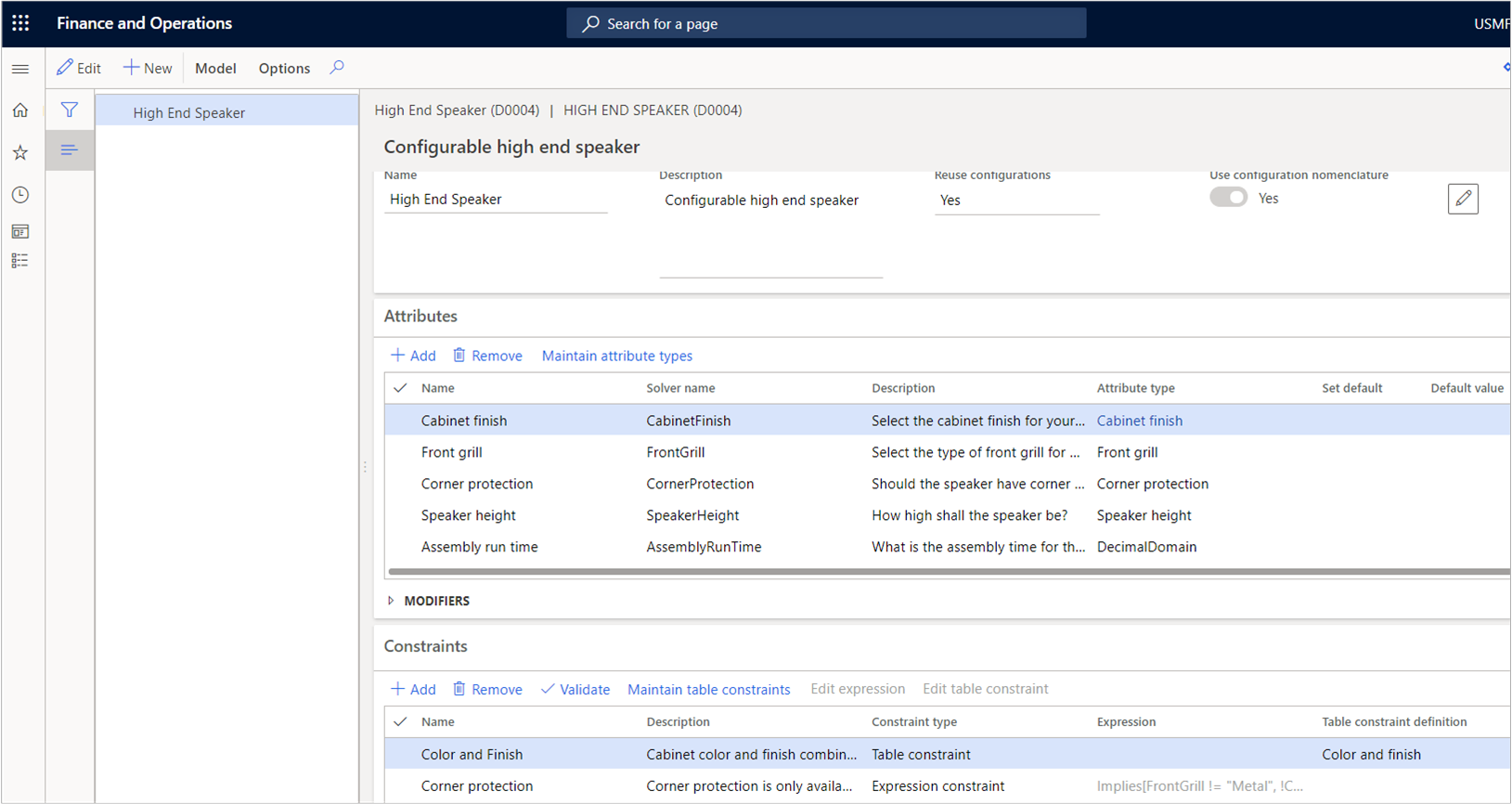

The product configuration feature set in Supply Chain Management includes a user interface that provides a visual overview of the product configuration model structure and a declarative constraint syntax that you don't have to compile. Therefore, companies that want to support a configuration practice can get started more easily. As the following units explain, a product designer no longer requires the support of a developer to build a product configuration model, test it, and then release it to the sales organization.

Scenario

The USMF company builds customized home theater systems. These home theater systems allow for many configurations, such as color of system, size of television, type of sound system, and number of speakers.

The product designer is setting up the home theater system in Supply Chain Management, with several configurations based on the room size, and wants to reuse the configuration setup from one room size to the next.

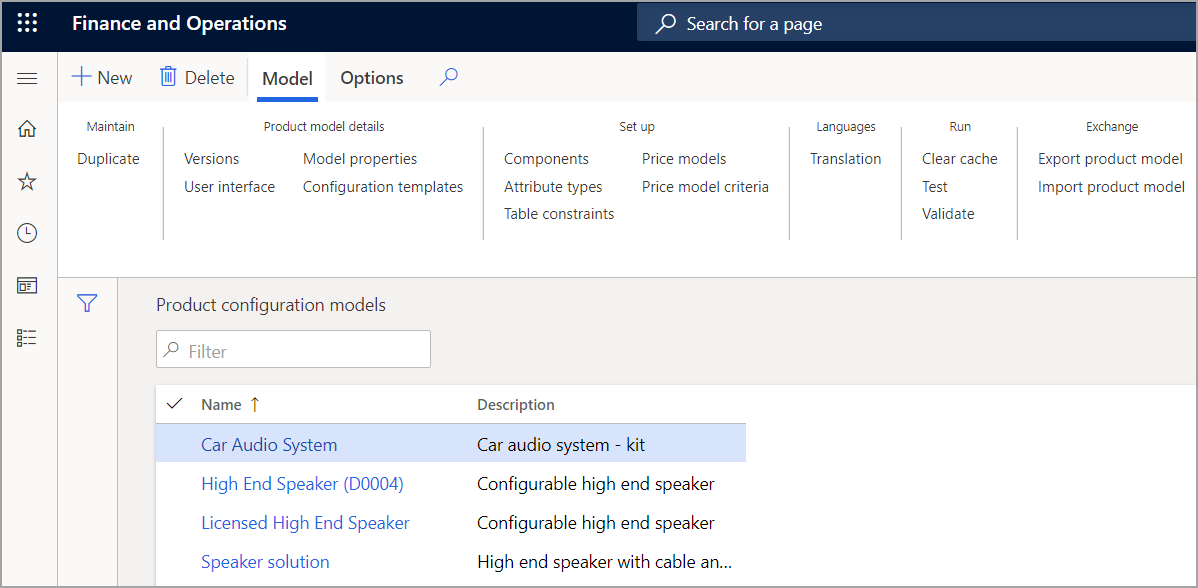

Because of the number of options for building the home theater system and the reusability of components, domains, and table constraints, the product designer must create a configuration model by using the Product information management > Products > Product configuration models page.

By using the product configurator, you can create and maintain configuration models.

For more information, see Get started with product configuration in Dynamics 365 Supply Chain Management.