Lean manufacturing for Microsoft Dynamics AX 2012: Event kanbans - the single piece flow

The ultimate lean goal – the single piece flow with zero inventories – is not an illusion. Many industries have been able to replace build to stock/supermarket by assemble to order scenarios that support single piece flow. Lean manufacturing for AX 2012 provides a powerful new instrument to support these scenarios: Kanban production and replenishment based on Events.

The best implementations of Lean manufacturing I have seen so far are mostly driven by a common pain: The explosion of item variants – for the most different reasons – makes it impossible to hold inventory on final product level, without running into a huge risk of holding excess inventory or even worse – constantly depreciating or expensing products that have been hold in the final product stock but cannot be sold based on material expiry or engineering changes.

The need to remove or at least reduce this huge waste of money and resources usually leads to the cleanest implementations of lean manufacturing. Final assembly, packaging and shipping activities are streamlined and aligned to the targeted sales lead time – shipping the product out of final assembly within a very short lead time, usually days or few weeks (ideally 1). Some industries – like JIS (just in sequence) in Automotive – reach lead times of 2.5 hours from call-off to shipment for an assembly process!!

No need to explain that this requirement lies beyond Master scheduling – even if some implementations of Microsoft Dynamics run a net-change on master scheduling in a frequency of 30 minutes.

The new Lean manufacturing framework of Microsoft Dynamics AX 2012 allows definition of kanban rules with the replenishment strategy Event. The creation of event kanbans based on this strategy is triggered by a source requirement and the new kanban is pegged to the source requirement.

The event kanbans replace the previously released modules of LOS-BTO Schedules (Lean order schedules – Build to order) and PTO Kanbans (Pull to order) that were part of Lean manufacturing for Microsoft Dynamics AX 2009 with a single

architecture.

The sales event

The sales event is triggered by the creation or a change of a sales line – no matter if this is happening manually, through enterprise portal or using the sales creation services of Microsoft Dynamics AX.

Each sales line creates one or multiple kanbans to fulfil the related demand, based on the maximum product quantity defined in the kanban rule that corresponds to the maximum handling unit size.

The kanban cards printed for sales event kanbans contain customer and customer order references and can be used as shipment labels for the handling units.

The kanban line event

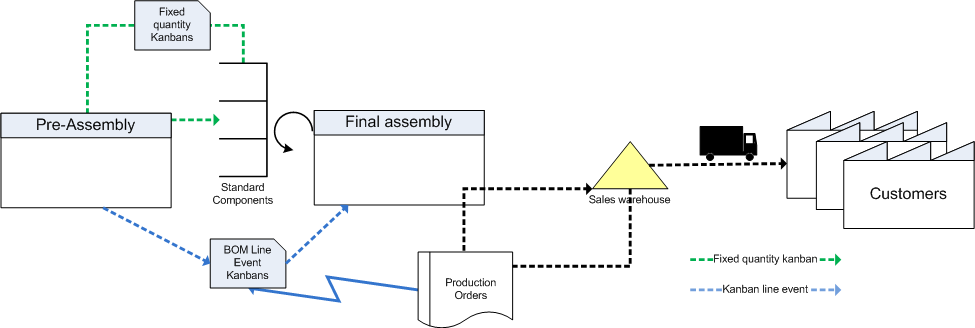

Kanban line events can be created to pull from a pre-processing activity. In the following example a lean work cell assembles painted parts (B) to finished products (A). The kanbans for A can be of any replenishment strategy – fixed, scheduled or event. While all standard colours – red, green or blue – are picked from a supermarket that is replenished as fixed quantity kanban, the special colours – gold and silver – create event kanbans.

Another application of kanban line events is transfer of material to a production location. In the following example we are assuming that products are produced on two sites 1 and 2, the related components are produced on site 1 and stored in a supermarket. While process B on Site 1 can directly pick from the supermarket, the material for process B on site 2 needs to be transferred to site 2.

By defining a kanban line event withdrawal rule for the transfer from site 1 to site 2 for the item relation All, transfer kanbans are created for all BOM-lines of items in Process B on Site 2. The related kanban transfer jobs can be grouped to consolidated shipments with non kanban material that needs to be transferred to Site 2.

The BOM line event

Like kanban lines, where the picking or transfer issues of a kanban trigger other kanbans, a production order can consume material that is supplied by lean manufacturing. Again, this can happen by picking from a supermarket or by creation of a BOM line event kanban, that pulls material to the production order.

On estimation of the production orders for the final assembly, the BOM Line event kanbans are created and loaded on the Pre-Assembly work cell.

The kanban rule can enforce a consistent reservation, to ensure that the components supplied by event kanbans are automatically reserved for the source of demand, in this case a production order.

Pegging event processing

In different application scenarios the volume of kanbans that are created based on events can be in a range of few event kanbans per day – where event kanbans only cover exceptions – to multiple kanbans per minute. To find the right balance between actual requirement view in the work cells and performance load each event definition on a kanban rule defines the kanban creation policy:

Automatic

The event kanbans are created with the source of demand. On the creation of

sales order lines the correspondent event kanbans are directly created,

allowing the work cell or warehouse to take immediate action on the new demand.

This setting is recommended to be used, when execution is expected to happen on

the same day.

Batch

Instead of the event kanbans a pegging requirement is created. A recurring

batch process that is independent of master scheduling is processing all new

pegging requirements. This light-weight process can be set up in the background

specific to selected production flows or activities ensuring an appropriate

reaction time for every application scenario.

Manual

When event processing is a pure exception taken on priority and capacity

considerations, an sales order line or a kanban can be manually selected to

create event kanbans.

The minimum stock event

When running master scheduling in Microsoft Dynamics AX, additional planned orders are created whenever minimum on-hand is reached. For a lean manufacturing application that surveys minimum on-hand of important parts, this might easily lead to a delay of a day until the signal for replenishment reaches the replenishing work cell. The pegging event processing in Lean manufacturing for AX 2012 checks minimum inventory for selected kanban rules and creates the needed kanbans to replenish instantly.

Lean manufacturing without event driven scenarios is only half the story. Lean manufacturing for Microsoft Dynamics AX 2012 provides a complete suite of tools to model any pull based scenario and scale the processes on volume and frequency of demand. The time effective nature of the kanban rules that model the scenarios support continuous modification and improvement. The bad news is: you can no longer use Microsoft Dynamics AX as the reason why you are not going Lean – it is all up to you now.

Comments

- Anonymous

August 11, 2013

During my work creating activities for the production flow, im not able to get the "quetime after" to work in planning purpose. The only time the system cares for is the run time. My Company really do need the quetime after since they paint things.Any suggestions? - Anonymous

August 13, 2013

Hi Helene,first of all, you should have R2 CU6 installed. Then I would recommend to review the Whitepaper "Lean manufacturing - Capable to promise and Kanban job scheduling":mbs.microsoft.com/.../LeanManufacturing_CapableToPromiseAndJobScheduling.pdfThis whitepaper explains the mechanics of scheduling for lean manufacturing. If you still have questions based on that, please let me know, then we might need to discuss your scenario in more depth. - Anonymous

July 02, 2014

ConradSome customers are getting confused about the routings still being available in Lean Manufacturing.My guess is that the decision was made to NOT shut off the routing functionality for Lean manufacturing and still allow establishing a standard cost using a traditional routing. But other then that the routing cannot play any role. If I have planned Kanbans (scheduled kanban), the route button is lit up and I don't think it should be. IF you want to use the routing for costing, it is not that easy. you have to create a symbolic costing resource, you can't use the workcell defined in the production flow.. I am inclined to say that the routing functionality should be shut off when the item is defined in a Kanban rule. What is your view? - Anonymous

July 02, 2014

Hi Evert,you are right that if you use the Route to calculate standard cost for an item that is the produced with a production flow, you will most probably see many variances in the backflush costing later.However, we do not configure products for a single purpose and a product that is - primarily - produced in a lean production flow could also be produced with a production order. This is why we are not thinging of deactivating the Route for products with default order type Kanban.Hope that helps.