Using the Work Policy for warehouse processes in production

Warehouse processes don’t always include warehouse work. By using the new warehouse work policy introduced with KB3184505, you can omit work warehouse processes in production for specific products and locations.

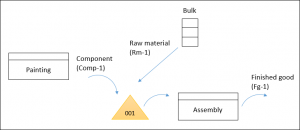

Below figure shows a scenario how the Work Policy can be used (double-click on the figures to make them bigger).

In this scenario, we have two production orders; one for painting Comp-1 and one for the assembly of Fg-1. The production order for Comp-1 is reported as finished to the location 001. The production order for Fg-1 is later consuming Comp-1 and Rm-1 from location 001. When the production order for Fg-1 is released, warehouse work for raw material picking is generated to move Rm-1 from the Bulk locations to 001.

For this scenario, we can set up following requirements for the warehouse processes:

- No warehouse work for Finished goods put away should be created when reporting as finished Comp-1 to location 001 because Comp-1 is later consumed on the same location by the Assembly operation.

- No Work for Raw Material Picking should be generated for Comp-1 when releasing the Assembly operation to the warehouse.

- Work for Raw material picking should be generated for Rm-1 when releasing the production order for the Assembly operation to the warehouse.

- It should be possible to define location 001 as non-license plate controlled, as it acts both as a production input location and a production output location (so far it has not been possible to define the production output location as non-license plate controlled).

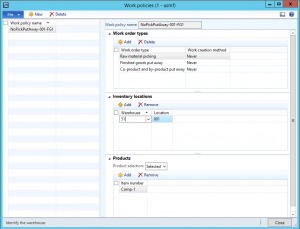

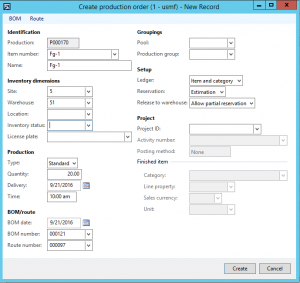

The following walkthrough shows how these requirements are supported by the Work Policy. First we will set up a Work policy named NoPickPutAway-001-FG1 as shown below

As it can be seen from the figure, the Work policy uses the following three criteria to define work creation:

- The Work Order Type

- The Location

- The Product (selected or all products)

Above policy will prevent Finished good put away work to be generated when Reporting as finished product Comp-1 to location 001 in warehouse 51.

The policy will also prevent Work for raw material picking to be generated when releasing a production order that is consuming product Comp-1 from production input location 001.

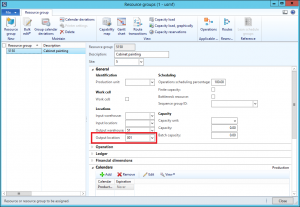

Location 001 is defined as a non-license plate controlled location. It is pre requisite for defining a non-license plate output location, that a work policy exists for the location that prevents work for Finished goods put-away from being created.

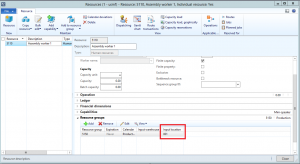

Let’s take a closer look at the setup of the products and then how the work policy works in this scenario. Product Comp-1 has a Painting operation which is associated a resource group with output location 001

The Assembly operation for the production order for FG-1 is consuming the products Comp-1 and RM-1 from the input location 001. The input location is setup on the resource requirements for the Assembly operation

The active bill of material version for Fg-1 is setup for materials Comp-1 and Rm-1

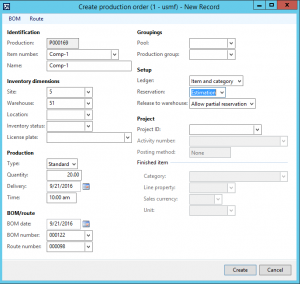

Now we create a production order for Comp-1 for 20 pieces

The production order is Started

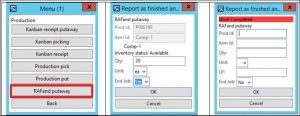

The production order is Reported as finished from the hand-held device in the below flow

In this case Comp-1 was reported as finished directly to location 001 and no put-away work was generated because of the Work policy.

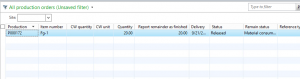

Now we create a production order for FG-1

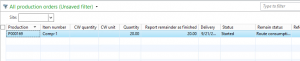

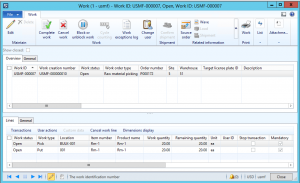

The production order is Estimated and Released

Work for raw material picking has been generated for Rm-1, because the Work policy is only preventing work for raw material picking for product Comp-1 to be generated from location 001

In the first release of the Work policy only the following three Work order types for production are supported

- Raw material picking

- Finished goods put away

- Co-product and by-product put away