Availability overview helps you calculate quantities in your warehouse

Important

This content is archived and is not being updated. For the latest documentation, go to What's new or changed in Business Central. For the latest release plans, go to Dynamics 365, Power Platform, and Cloud for Industry release plans.

| Enabled for | Public preview | General availability |

|---|---|---|

| Users by admins, makers, or analysts |  Sep 8, 2023

Sep 8, 2023 |

Oct 2, 2023

Oct 2, 2023 |

Business value

Increase warehouse handling efficiency by having accurate and real-time information about inventory levels, locations in your warehouse, processing stage, and other factors that affect available quantities—for example, quarantine or reservations.

Feature details

From source documents such as sales orders, production orders, assembly orders, or jobs, you can access information about the availability of items in your warehouse. The information is real-time, and respects factors that affect availability, such as dedicated bins, locked bins, and items that aren't available for picking. For example, items might be reserved, or pending put-away or shipment operations. The Pick Summary page lets you review the items that Business Central didn’t include in pick documents and take the necessary actions.

Scope

Available for locations that are configured to use Directed Put-away and Pick.

How to start

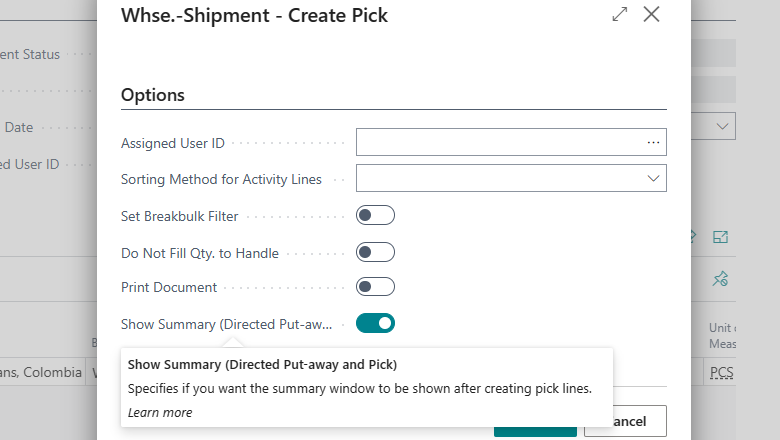

To get details on what's being picked and what isn't, turn on the Show Summary (Directed Put-away and Pick) toggle on the Whse.-Source - Create Document or Whse.-Shipment - Create Pick request pages.

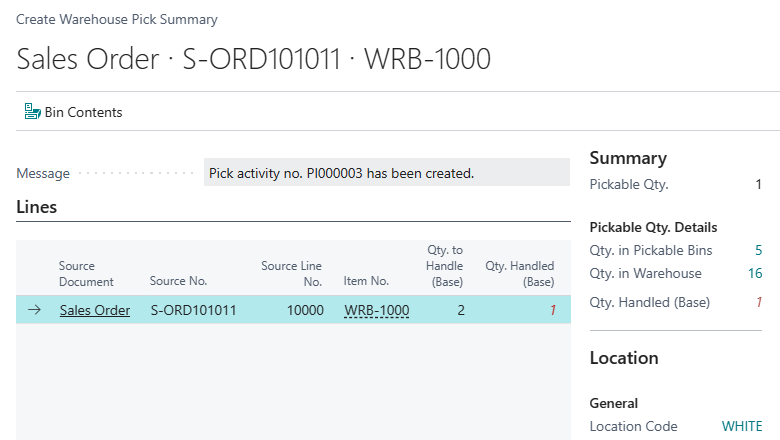

Pickable quantity

The lines show which, and how many, items that Business Central tried to pick in the Qty. to Handle (Base) field. They show how successful it was in the Qty. Handled (Base) field. The Summary FactBox provides additional details.

In simple cases you can find answers in the Pickable Qty field, which shows how many items are available.

You can explore bin content, which can help you to understand why the pickable quantity is less than you expected.

The Quantity in Warehouse field shows the total quantity you'll find in the warehouse if you do a physical count. You can drill down into warehouse ledger entries from this field. If the Quantity in Warehouse is less than the Quantity in Pickable Bins, there's a misalignment between warehouse and inventory quantities. In that case, use the Calculate Warehouse Adjustment action on the Item Journal page and then create the warehouse pick again.

The Pickable Qty. specifies the maximum quantity that Business Central can consider for picking. This quantity consists of items in pickable bins and excludes quantities that are in blocked or dedicated bins, or items that are being picked (quantity in warehouse pick documents). If the item you want to pick requires item tracking, then blocked lots or serial numbers stored in pickable bins are excluded from the pickable quantity.

If the Pickable Qty is different than Qty. in Pickable Bins, you might want to explore the bin content to find blocked bins or quantities in active documents.

Impact of reservations

If there are reservations for the item being picked, then calculation continues. The idea is that reserved demand has higher priority than non-reserved, which means that picking for non-reserved demand shouldn't prevent picking for reserved demand later.

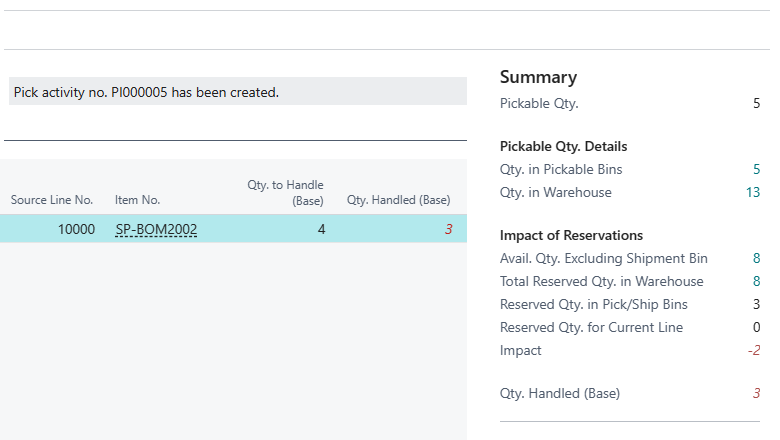

The screenshot shows that the Pickable Qty is enough to cover the Qty. to Handle (Base).

However, this demand isn't reserved, and there's another demand that is reserved from the stock. You can find reservations in the Total Reserved Qty. in Warehouse field. Some of the reserved quantity is already picked and ready for shipment, usage, or consumption, and shouldn't affect the availability calculation. You can see this quantity in the Reserved Qty. in Pick/Ship Bins.

The screenshot shows that the Reserved Qty. in Pick/Ship Bins is 3, which reduces the reserved quantity in the warehouse from 8 to 5.

It might seem like the pickable quantity is 5, so we can't pick anything without preventing picking for reserved demand. That isn't exactly true. While we don't want to make it impossible to pick, we should be reasonable. As we figured out, the total quantity in the warehouse is 13. If we reduce this by removing quantities that are out of reach, such as quantities picked for shipment, they can be already loaded into trucks, or picked for consumption, which means these quantities might be already processed in machine center. It also makes sense to exclude blocked item lots or serial numbers and quantities in blocked bins. What's left, which you can find in the Avail. Qty. Excluding Shipment Bin field, is potentially available. It can't be picked right away because this quantity is still in the receipt, storage, or quality assurance areas, but it can be reasonably faster moved to picking area either by processing a put-away or movement worksheet.

The difference between Avail. Qty. Excluding Shipment Bin and reserved quantity in warehouse is the quantity available for picking without impacting reserved stock. In our example, it will be 8 - 5. The pickable quantity should be reduced to 3 (impact on pickable qty is -2).

Other details

If items require item tracking, you can find the quantity in blocked lots or serial numbers as well, which reduces the pickable quantity, available quantity excluding the shipment bin, and the reserved quantity in the warehouse.

If you pick the same item for multiple source documents or lines, which is also the case when you pick serial numbers, information about picks for other lines also displays because it reduces the pickable quantity.

Technical warning

When implementing this overview, we changed the sequence of checks. On the one hand, that reduced the number of calls and improved the overall performance and reliability of warehouse picks. On the other hand, some events aren't called or are called less often. This might impact solutions that adjust availability calculations.

The following are the events in the CreatePick.codeunit.al that are affected:

- OnAfterCalcQtyOnPickAndReceiveBins

- OnBeforeCalcQtyOnOutboundBins (triggered within WarehouseAvailabilityMgt.CalcQtyOnOutboundBins(....))

- OnAfterGetOutboundBinsOnBasicWarehouseLocation (triggered within WarehouseAvailabilityMgt.CalcQtyOnOutboundBins(....))

- OnAfterCalcQtyOnBlockedITOrOnBlockedOutbndBins (triggered within WarehouseAvailabilityMgt.CalcQtyOnBlockedITOrOnBlockedOutbndBins(...))

- OnCalcTotalAvailQtyToPickOnBeforeCalcSubTotal

- OnBeforeAdjustQtyReservedOnPickShip (triggered within AdjustQtyReservedOnPickShip(...))

Tell us what you think

Help us improve Dynamics 365 Business Central by discussing ideas, providing suggestions, and giving feedback. Use the forum at https://aka.ms/bcideas.