Enable intelligent factories

Microsoft Cloud for Manufacturing enables the intelligent factory of the future by using Industrial IoT, data analytics, AI, and cloud connectivity to extract critical data from across OT & IT to drive improvements in Overall Equipment Efficiency (OEE), operations visibility, and sustainability. Manufacturers can seamlessly share real-time production insights from the data with the design and engineering teams. The insights facilitate collaboration and improve manufacturing processes based on real-world feedback and lead to continuous improvements and innovation.

Machine learning models enhance product quality within the intelligent factory by helping manufacturers detect and address defects in real-time, ensuring the production of high-quality products. Finally, the Microsoft Cloud for Manufacturing solution provides communication and collaboration tools that enable frontline workers to easily connect and collaborate. This solution facilitates faster onboarding processes, enables efficient up-skilling of workers and ensures that they have the necessary knowledge and expertise to operate within the intelligent factory environment.

Microsoft supports manufacturing customers to enable intelligent factories by focusing on these core scenarios.

Connected and Enabled Workers

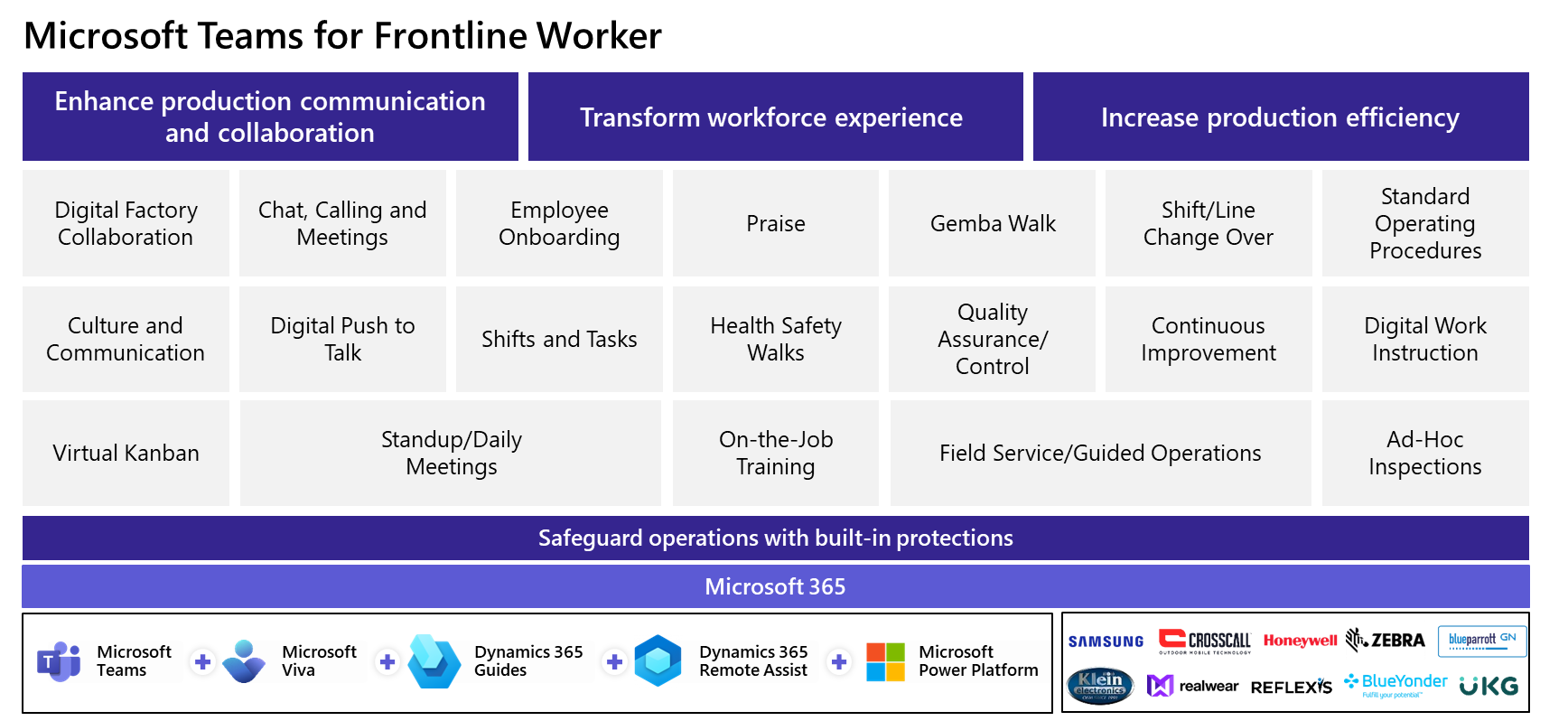

Microsoft provides frontline workers with a unified platform that facilitates streamlined communication, enhances employee experiences, promotes agile operations, and offers comprehensive enterprise-grade security capabilities. This platform helps to consolidate your technology investment. It enables the centralization of your organization’s communications and business processes across manufacturing environments into one app to create a comprehensive view for the frontline workforce.

The top Connected and Enabled Workers use cases supported by Microsoft include:

- Enhance production communication and collaboration: Scale up expertise and reduce downtime by connecting workers with the right people, tools, and knowledge to do their job done.

- Transform workforce experiences: Empower new hire onboarding, build skills, and engage in an inclusive company culture.

- Increase production efficiency: Automate task and OT processes with digital workflows and connect to systems of record.

- Safeguard operations with built-in protections: Secure your business with built-in security and compliance across endpoints and devices.

The key Microsoft technologies that support Connected and Enabled Workers are:

- Microsoft Teams for Frontline Workers

- Microsoft Viva

- Microsoft HoloLens 2

- Microsoft Power Apps

- Dynamics 365 Guides

- Dynamics 365 Remote Assist

In addition to the Microsoft technologies that support Connected & Enabled Workers, learn more about Microsoft’s growing ecosystem of hardware partners, from ruggedized phones to wired or wireless headsets at Microsoft AppSource.

The following partner solutions certified for Microsoft Cloud for Manufacturing support the Connected and Enabled Workers use cases described earlier and are available on Microsoft AppSource.

These solutions are certified with the Microsoft AI Cloud Partner Program and meet the Microsoft standards of data accessibility specific to the manufacturing industry. To learn more about the Microsoft Cloud for Manufacturing certified partner solutions and the Microsoft AI Cloud Partner Program, see Appendix: Certified partner solutions for Microsoft Cloud for Manufacturing.

Don't see your solution here? Check out Microsoft AppSource for the full list of ISV solutions.

Production Monitoring and Optimization

Microsoft provides a comprehensive suite of solutions to help manufacturers harness the power of production data and drive intelligent decision-making within their factories. By using data captured through the utilization of sensors, machines, programmable logic controllers (PLCs), factory systems, and enterprise systems (IT), manufacturers gain valuable insights across the factory floor that lead to optimized operations, reduced number of bottlenecks, and enhanced overall efficiency.

The top Production Monitoring and Optimization use cases supported by Microsoft include:

- Factory Digital Twins: Provides a structured, graphical digital data platform that can enable use cases from production monitoring to process optimization, simulation, and maintenance.

- MES on Azure: Offers manufacturers the agility, scalability, and cost-efficiency required to adapt to rapidly changing market conditions and drive digital transformation in their manufacturing operations.

- Edge and OT Security: Encompasses coverage and visibility of IoT/OT devices, risk analysis across all networks, behavioral analytics, and rapid identification and mitigation of multi-stage attacks across IT/IoT/OT.

- Sustainable Operations through Energy Cost Optimization: Helps to reduce energy costs by optimizing the consumption and achieving sustainability goals by reducing carbon footprint.

- Autonomous and Intelligent Control Systems: Use AI and ML technologies to optimize processes, enable quality inspection, automate tasks, optimize machine performance, and facilitate easy access and summarization of data.

The following are the key Microsoft technologies that support the Production Monitoring & Optimization use cases:

The following partner solutions certified for Microsoft Cloud for Manufacturing support the Production Monitoring & Optimization use cases described earlier and are available on Microsoft AppSource.

- Sight Machine on Azure

- AVEVA Data Hub

- Cognite Data Fusion®

- PTC ThingWorx Digital Performance Management

- Rockwell Plex

- TCS Digital Manufacturing Platform

These solutions are certified with the Microsoft AI Cloud Partner Program and meet the Microsoft standards of data accessibility specific to the manufacturing industry. To learn more about the Microsoft Cloud for Manufacturing certified partner solutions and the Microsoft AI Cloud Partner Program, see Appendix: Certified partner solutions for Microsoft Cloud for Manufacturing.

Don't see your solution here? Check out Microsoft AppSource for the full list of ISV solutions.

Maintenance and Quality

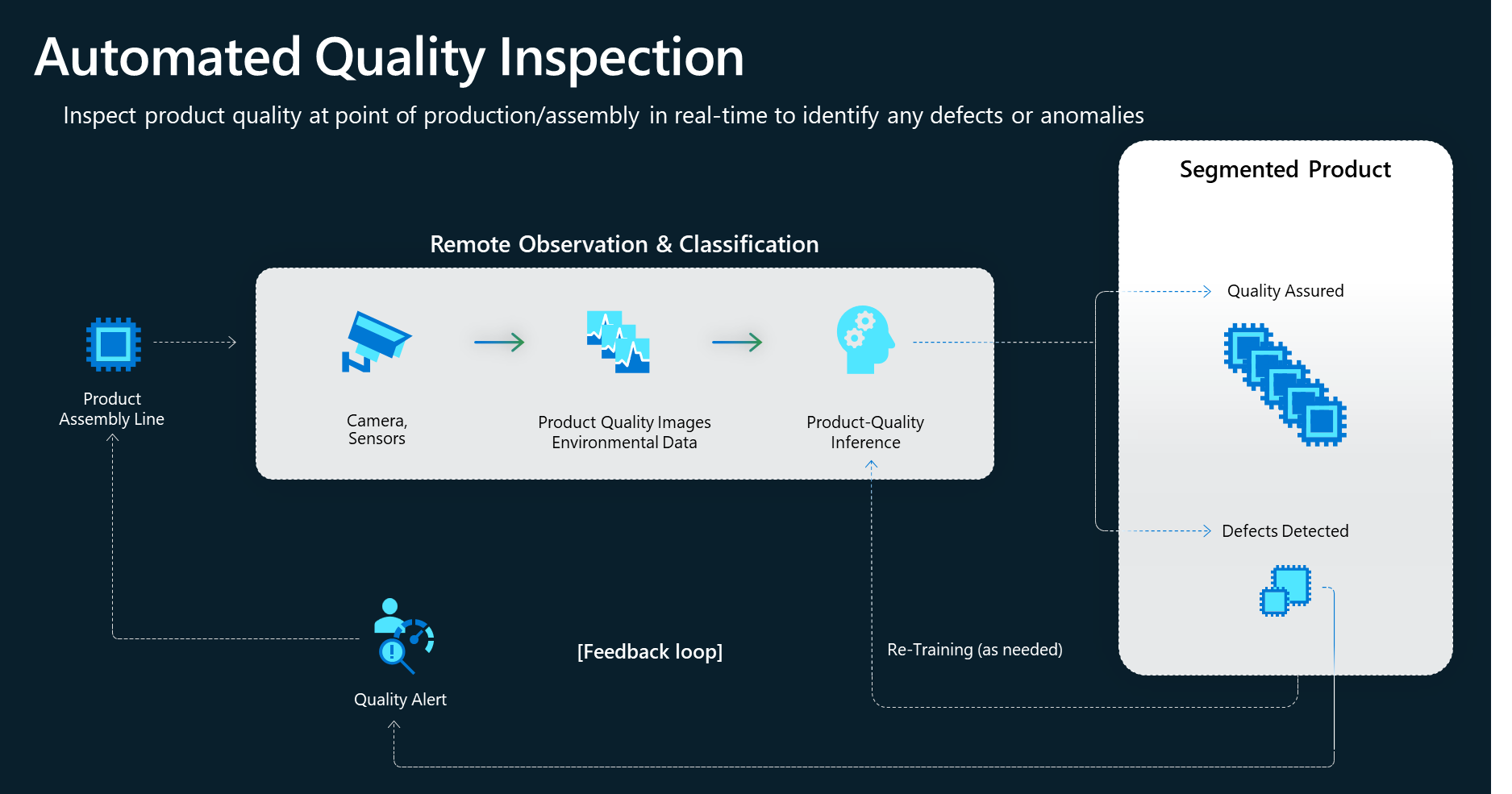

Maintenance and Quality refer to the use of applications and AI-based solutions to track materials within the factory, automate complex quality inspection processes, and launch predictive maintenance solutions. It involves using intelligent systems to automate complex quality inspection processes, roll out computer vision models to detect defects, analyze machine data for root cause analysis, and share real-time production insights back into design and engineering to ensure that materials and final products meet predefined standards. Manufacturers can enhance operational efficiency and significantly reduce errors to ensure consistent product quality and enable a more streamlined manufacturing process.

The top Maintenance and Quality use cases supported by Microsoft include:

- Production Quality: Uses in-line, off-line, pre & post build solutions to capture quality issues while occurrence and bring improved recovery. Augment human quality inspection through AI and cognitive capabilities for scenarios like automated & 100% inspection.

- Predictive Maintenance: Uses a combination of sensors, artificial intelligence, and data science to optimize equipment maintenance, predict equipment maintenance needs to minimize maintenance costs and maximize uptime to provide significant value to manufacturers.

The following are the key Microsoft technologies that support the Maintenance and Quality use cases:

The following Microsoft Cloud for Manufacturing certified Independent Software Vendor (ISV) solutions support the Maintenance and Quality use cases described earlier and are available on Microsoft AppSource.

These solutions are certified with the Microsoft AI Cloud Partner Program and meet the Microsoft standards of data accessibility specific to the manufacturing industry. To learn more about the Microsoft Cloud for Manufacturing certified partner solutions and the Microsoft AI Cloud Partner Program, see Appendix: Certified partner solutions for Microsoft Cloud for Manufacturing.

Don't see your solution here? Check out Microsoft AppSource for the full list of ISV solutions.