Data models in Microsoft Cloud for Manufacturing (preview)

Manufacturing data solutions helps you manage and analyze data from multiple domains within manufacturing. These domains span the value stream like design and engineering, supply chain planning, operations management, energy and sustainability management, product costing, and distribution management. Manufacturing data solutions use open, industry-standard ontologies and models to realize this vision in a phased manner.

The first target domain for manufacturing data solutions is Manufacturing Operations Management (MOM). This domain supports production personnel to take data driven decisions and improve efficiency within their operations.

The purpose of manufacturing data solutions is to harmonize the customer's data, from different systems across operational technology (OT), information technology (IT), and engineering technology (ET). This enables interoperability and a unified consumption experience. Manufacturing data solutions strives to achieve this objective by:

Defining a consistent data model based on open industry standards that best represents each domain. This way, you can uniformly represent data from different systems. The industry data model also solves interoperability issues because it uses open-standards-based model with proven adoption. This model ensures that you and your partners already know the underlying semantics. It also democratizes the data access for citizen and domain expert personas since the semantic model enables low-code consumption approaches.

Curating a semantic knowledge graph using the data model. The knowledge graph adopts the entities and relationships from the open standard. It provides the necessary connections and grammar, aiding generative AI based assistants to derive meaning, find correlations, and derive patterns for causality and reasoning within the data.

The manufacturing data model is based on the ISA95 (IEC 62264) standard, which is the leading industry standard for MOM. This model forms the basis for the Manufacturing Execution System (MES) and many of the shop-floor systems for production, quality, maintenance, and inventory management.

The following sections dive deeper into the ISA95 based data model of manufacturing data solutions.

Common and resource data models

Manufacturing data models covers the common and resource data models based on the part-1 and part-2 of ISA95 specification. These data models provide the context for any manufacturing activity by answering basic questions like:

- What materials, equipment, or personnel skills are needed to produce an item?

- How much of each resource is needed?

- Where can it be produced?

Common models

The common data models describe certain common patterns (example hierarchies) or models that describe spatial or location data.

Hierarchy scope

The hierarchy scope identifies where the exchanged information fits within the role-based equipment hierarchy. It defines the scope of the exchanged information, such as a site or area for which the information is relevant. The hierarchy scope identifies the associated instance in the role-based equipment hierarchy.

Spatial definition

The spatial models specify where a manufacturing operation is being performed. The spatial definition provides a means of communicating zero-dimensional points, one-dimensional line, or two-dimensional shape or three-dimensional solid geospatial location data for planning/scheduling, actuals, resources, and analytics. Spatial definition identifies a value and the predefined coordinate reference system.

Operational location

Operational locations refer to the logical or physical areas within a plant where resources are, or are anticipated to be, situated. Operational locations may be made up of smaller operational locations.

Resource models

The resource data models describe the logical or physical resources needed to perform any operation step in manufacturing. These steps can be related to production, quality, inventory, or maintenance operations.

The resource data models contain the equipment (expressed as logical hierarchies), personnel with certain skill set, material (with certain properties and corresponding stock information), and physical assets. The resource data models also contain a process definition view in the form of a process segment that describes the collection of steps and their relationships needed to perform any manufacturing related activity in the production, maintenance, quality, or inventory departments.

Role-based equipment information

This model contains information about specific equipment, and the classes of equipment. The information is used to construct the hierarchical models used in manufacturing scenarios. The defined equipment levels specified in the equipment level attributes, for role-based equipment are enterprise, site, area, work center, work unit, process cell, unit, production line, production unit, work cell, storage zone, and storage unit. Role-based equipment defines the logical capabilities of the equipment than its physical make and model.

The following diagram depicts the equipment hierarchy:

Physical asset information

This model contains information about the physical piece of equipment, managed as a physical asset within the enterprise often having a specific serial number. An object in the equipment model defines a role for the equipment, and an object in the physical asset model defines the physical asset ID and properties of a piece of equipment.

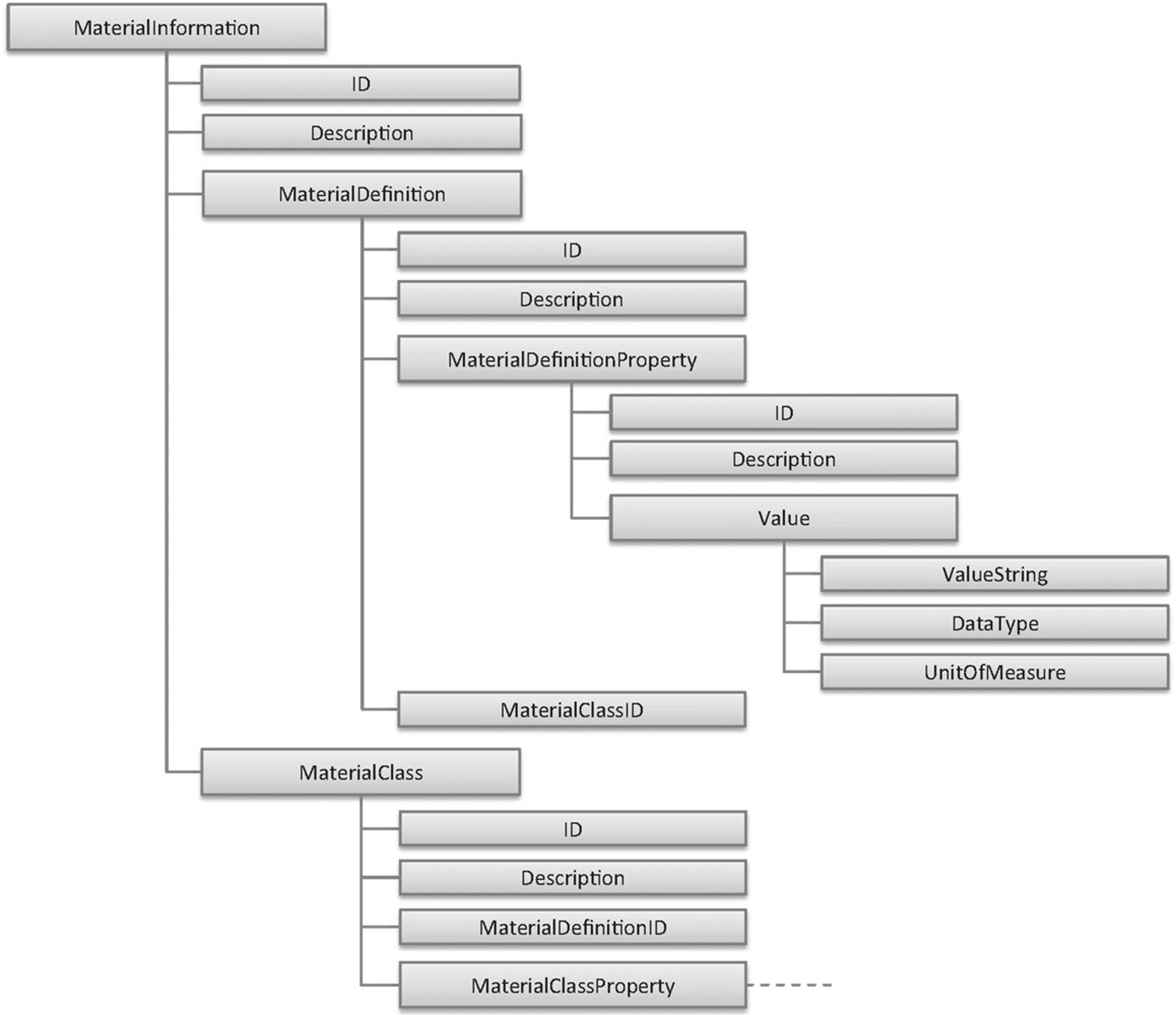

Material information

This model integrates the master data related to material classes, individual material definitions, and the inventory / stock related information in one combined framework. Material information includes the inventory of raw, finished, intermediate materials, and consumables. The information about planned or actual material is contained in the material lot and material sublot models. Material classes are defined to organize materials into logical groups. The following diagram shows some relevant parts of the model.

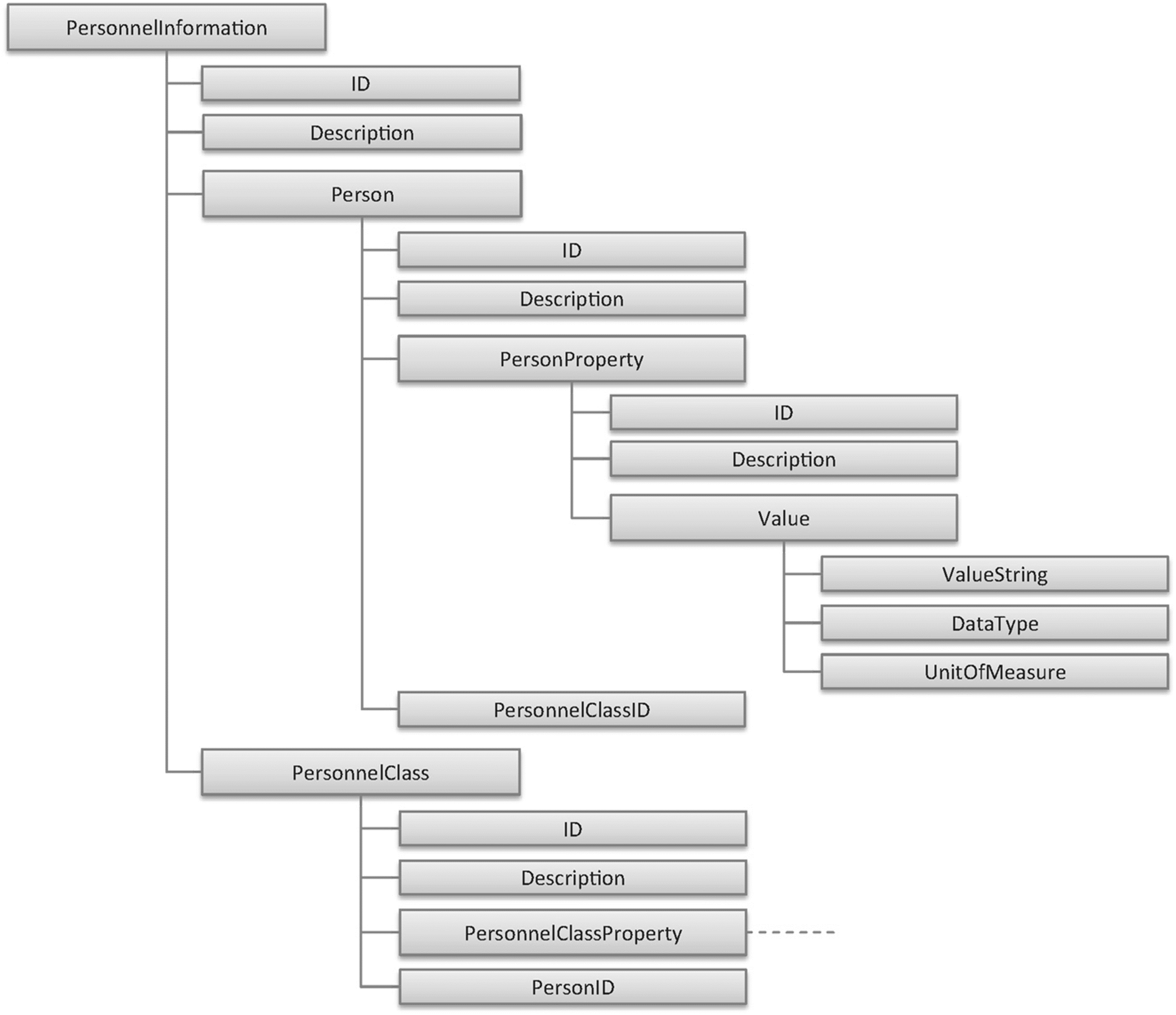

Personnel information

This model contains information about specific personnel, classes, and qualifications.

Process segment information

The process segment model is a hierarchical model, in which multiple levels of abstraction of manufacturing processes may be defined because there can be multiple business processes requiring visibility to manufacturing activities.

A process segment is the smallest element of manufacturing activities that are visible to business processes. It's the logical grouping of personnel resources, equipment resources, physical asset resource, and material required to perform a manufacturing operations step. The manufacturing operations step may be a production operations step, inventory operations step, maintenance operations step, and quality operations step.

A process segment defines the needed classes of personnel, equipment, physical assets, and material, and/or it may define specific resources, such as specific equipment needed. A process segment may also define the quantity of the resource needed. The following diagram shows the representative parts of the process segment indicating relationships to other parts of the resource model.

Together, these common and resource data models contextualize any manufacturing process step (segment) by providing answer to the "what", "where", "how", "by whom" or "using what" questions.

Operational models

Operational models deal with the interface between manufacturing activities that happen within a production plant and other business systems of an enterprise. There are four categories of manufacturing operations information that correspond to the four categories of manufacturing operations activities as shown in the following diagram.

In addition, there are two other models that support the over-all information capture.

Operations schedule (request) information

This model gives details of the planned and production orders received from business systems. It typically contains information about requests to perform work within one or more categories of activities. It defines what production, maintenance, testing, or material movements to do, when to do them or when they're due, and what resources to use. It identifies the resources and properties using reference to the resource models. The following diagram captures the relevant parts of the operations schedule model.

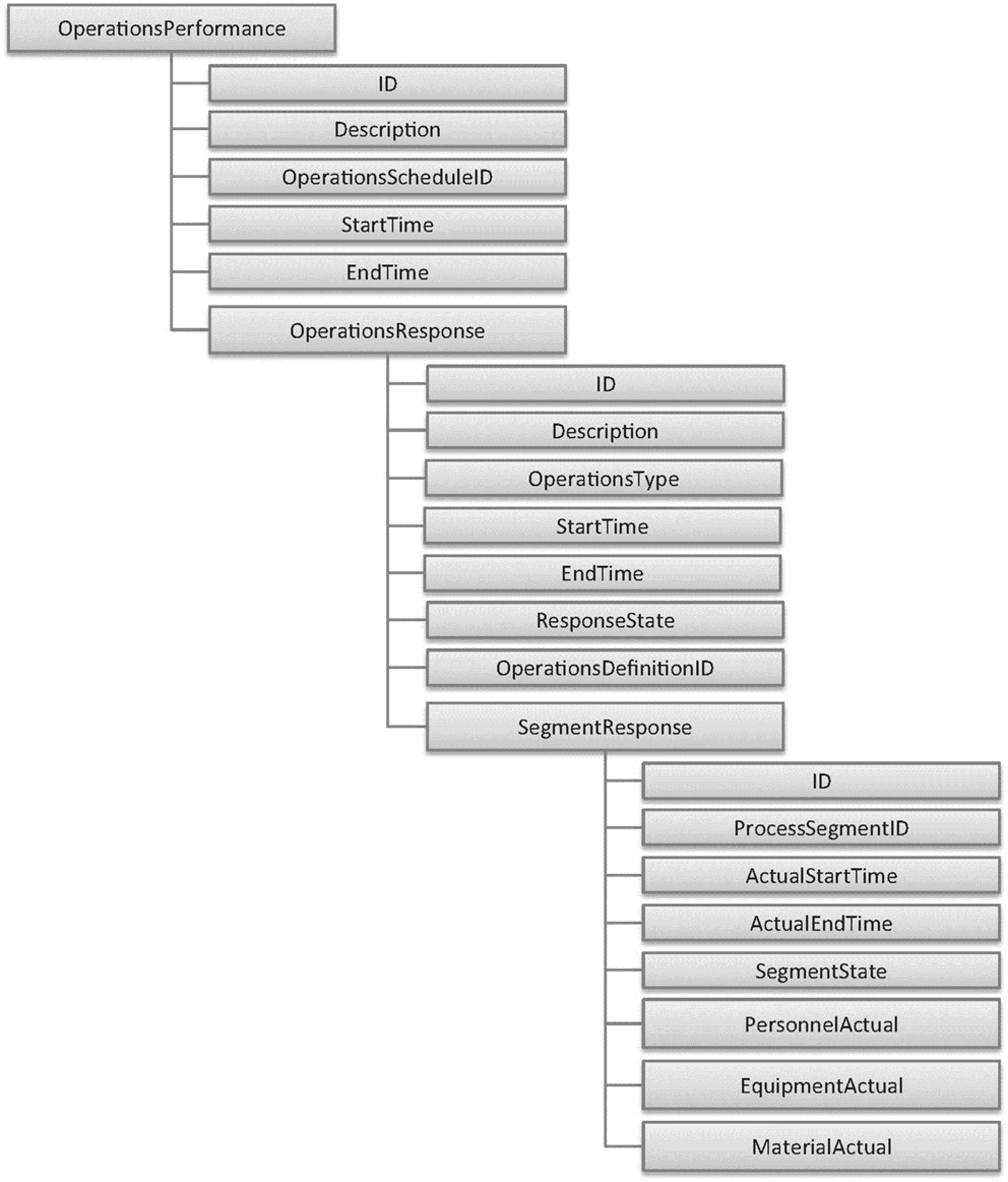

Operations performance (response) information

This model provides information about work performed within one or more categories of activities. Operations performance defines the information sent because of executing the schedule. It defines what production, maintenance, testing, or material movements were done, when they were done, and what resources were used.

Operations capability information

This model provides information about the capabilities to perform work within one or more categories of activities. Operations capabilities define the capabilities and capacities that are available for production, maintenance, testing, or material movements for a specific time duration. It also defines the capabilities that may be available to execute specific process segments.

Operations definition information

This model provides information about the capabilities to perform work within one or more categories of activities. Operations capabilities define the capabilities and capacities that are available for production, maintenance, testing, or material movements for a specific time duration. It also defines the capabilities that might be available to execute specific process segments.

Operations event model

MES systems and many other shop floor systems generate event information (example: order processed; x KG of material consumed etc.). The operations event model captures these events and links them. to the resource models via, the hierarchical scope. Many of the unplanned events (for example, unplanned downtime) or alerts from factory control systems are also captured and passed via the operations event model.

Operations test model

MOM information includes the quality testing data generated via shop floor testing or independent tests in Laboratory Information Management Systems (LIMS). The operation test model captures the test planning (what tests, which parameters) and the result of those tests. The operation test model is linked to all other "testable" objects – including resource models and operations models. For example, test specifications and results can be linked to equipment, material and their samples, process steps within orders or schedules or even for personnel (certifications).

Work models

The work models cover the most granular level information exchanged between the activities of an MES. The following information models are part of the work models:

Resource relationship network: This model is created by tasks in resource management and definition management activities.

Work definition:

Work master: This model is created by an engineering activity and to be managed by a task in definition management activities.

Work directive: This model is created by a task in execution management activities.

Work schedule: This model is created by a task in detailed scheduling activities.

Job list: This model is created by a task in dispatching activities. Here the term job can sometimes be used instead of job order when referring to an entry in a job list.

Work performance: This model is created by a task in tracking activities.

Work capability: This model is created by a task in resource management activities.

Work master capability: This model is created by a task in resource management activities.

Work alert: This model might be created by any activity in the MES activity list.

Work calendar: This model might be created by any activity in the MES activity list.

How all data models fit together

The following diagram fits all this data models together based on ISA95 standard:

The three sections include:

Master or reference data for manufacturing captured via the resource models, which provide the context for any manufacturing operation step.

Interface data where MOM exchange the operation data with business systems.

Lower-level work data exchanged within the MOM activities typically inside an MES system.

Together, these models allow uniform modeling of the MOM domain of an enterprise with all details and levels of hierarchy.