Hi there.

I may be late with my answer, nevertheless, I will share my contribution. it may be be helpful.

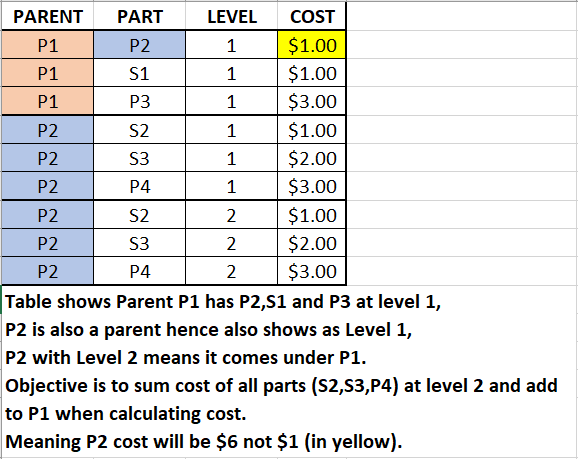

When one talks about "cost rollup" that means a bit different thing than what it's called here.

As @Erland Sommarskog and @Tom Phillips pointed out, it can get complicated and the provided input data is unclear in definitions. it is missing to mention if qty is QPA or extended qty. also, structures need to be normalized and cost normally is not stored with BOM itself.

Here is a dramatic simplification of T-SQL code I have in production, to demonstrate this.

I hope I have not made any bug in my effort to simplify it from my production code.

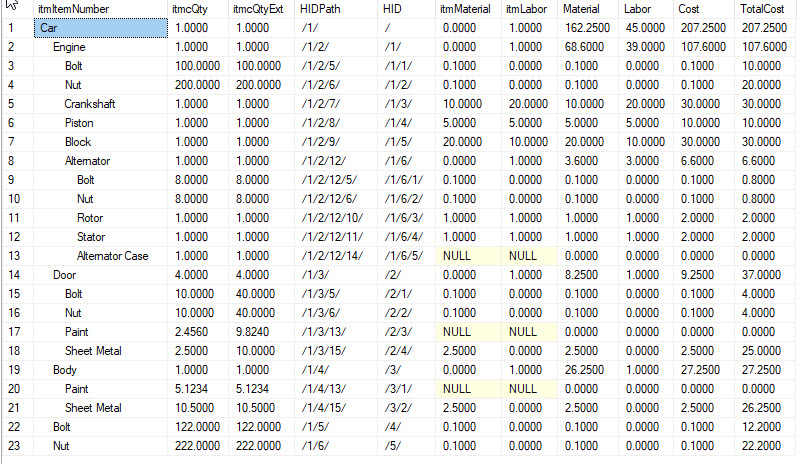

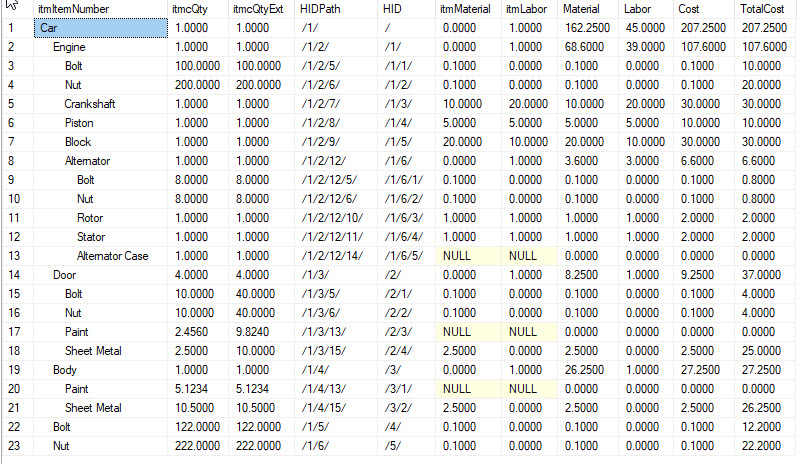

I made up a car example to show how it works. I hope my example is sufficient.

use tempdb

GO

BEGIN TRANSACTION

-- trivialized representation

CREATE TABLE dbo.Items -- or parts, sub-assemblies and assemblies, item master

(

itmID int NOT NULL

,itmItemNumber nvarchar(50) NOT NULL

--,itmDescription nvarchar(100) NOT NULL

--,PrimaryUOMCode nvarchar(5) NOT NULL

,CONSTRAINT PK_Items_itmID PRIMARY KEY CLUSTERED(itmID)

,CONSTRAINT UX_Items_itmItemNumber UNIQUE(itmItemNumber)

)

CREATE TABLE dbo.ItemCosts -- item/part unit costs, also trivialized

(

itmID int NOT NULL

,itmMaterial decimal(9, 4) NOT NULL

,itmLabor decimal(9, 4) NOT NULL

,CONSTRAINT PK_ItemCosts_itmID PRIMARY KEY(itmID)

,CONSTRAINT FK_ItemCosts_Items FOREIGN KEY (itmID) REFERENCES dbo.Items(itmID)

)

-- Engineering structure

CREATE TABLE dbo.ItemComponents -- or sub-assembly membership, or parent to parts relations. it defines what and how much goes into each sub-assembly

(

itmID int NOT NULL -- parent

,CompItmID int NOT NULL -- components

,itmcQty decimal(9, 4) NOT NULL -- QPA, quantity per assembly

,CONSTRAINT PK_ItemComponents_itmID_CompItmID PRIMARY KEY CLUSTERED(itmID, CompItmID)

,CONSTRAINT FK_ItemComponents_Items FOREIGN KEY (itmID) REFERENCES dbo.Items(itmID)

,CONSTRAINT FK_ItemComponents_Items_Comp FOREIGN KEY (CompItmID) REFERENCES dbo.Items(itmID)

)

INSERT INTO dbo.Items

VALUES

(1, 'Car')

,(2, 'Engine')

,(3, 'Door')

,(4, 'Body')

,(5, 'Bolt')

,(6, 'Nut')

,(7, 'Crankshaft')

,(8, 'Piston')

,(9, 'Block')

,(12, 'Alternator')

,(10, 'Rotor')

,(11, 'Stator')

,(13, 'Paint')

,(14, 'Alternator Case')

,(15, 'Sheet Metal')

INSERT INTO dbo.ItemCosts

VALUES

(1, 0, 1) -- 'Car'

,(2, 0, 1) -- 'Engine'

,(3, 0, 1) -- 'Door'

,(4, 0, 1) -- 'Body'

,(5, 0.1, 0) -- 'Bolt'

,(6, 0.1, 0) -- 'Nut'

,(7, 10, 20) -- 'Crankshaft'

,(8, 5, 5) -- 'Piston'

,(9, 20, 10) -- 'Block'

,(12, 0, 1) -- 'Alternator'

,(10, 1, 1) -- 'Rotor'

,(11, 1, 1) -- 'Stator'

,(15, 2.5, 0) -- 'Sheet Metal'

INSERT INTO dbo.ItemComponents

VALUES

(1, 2, 1)

,(1, 3, 4)

,(1, 4, 1)

,(2, 7, 1)

,(2, 8, 1)

,(2, 9, 1)

,(2, 5, 100)

,(2, 6, 200)

,(2, 12, 1)

,(12, 10, 1)

,(12, 11, 1)

,(12, 5, 8)

,(12, 6, 8)

,(12, 14, 1)

,(1, 5, 122)

,(1, 6, 222)

,(4, 13, 5.1234)

,(3, 13, 2.456)

,(3, 5, 10)

,(3, 6, 10)

,(3, 15, 2.5)

,(4, 15, 10.5)

CREATE TABLE dbo.OrderBOMs -- proper BOM tree, expanded into acyclic tree with single root.

(

bomID int NOT NULL -- normally order specific bill ID, for specific customer order that needs manufacturing

,itmID int NOT NULL

,itmIDParent int NULL

,HIDPath hierarchyid NOT NULL -- lineage using itmID

,HID hierarchyid NOT NULL -- proper hierarchy id

,itmcQty decimal(9, 4) NOT NULL -- QPA

,itmcQtyExt decimal(9, 4) NOT NULL -- QPA extended, total per BOM

,CONSTRAINT PK_Items_HID PRIMARY KEY CLUSTERED(bomID, HID)

,CONSTRAINT FK_OrderBOMs_Items FOREIGN KEY (itmID) REFERENCES dbo.Items(itmID)

,CONSTRAINT FK_OrderBOMs_Items_Parent FOREIGN KEY (itmIDParent) REFERENCES dbo.Items(itmID)

)

DECLARE @itmItemNumber nvarchar(50) = N'Car'

;WITH tree AS

(

SELECT

CompItmID = itm.itmID

,itm.itmID

,itmcQty = CAST(1 as decimal(9, 4))

,itmcQtyExt = CAST(1 as decimal(9, 4))

,HIDPath = CAST(CONCAT('/', itm.itmID, '/') as varchar(8000))

,0 as IsCycle

,HID = CAST('/' as varchar(8000))

FROM dbo.Items itm

WHERE itm.itmItemNumber = @itmItemNumber

UNION ALL

-- get all direct components

SELECT

ic.CompItmID

,ic.itmID

,ic.itmcQty

,CAST(r.itmcQty * ic.itmcQty as decimal(9,4)) as itmcQtyExt

,CAST(CONCAT(r.HIDPath, ic.CompItmID, '/') as varchar(8000)) as HIDPath

,CASE WHEN r.HIDPath LIKE CONCAT('%/', ic.CompItmID, '/%') THEN 1 ELSE 0 END as IsCycle

,HID = CAST(CONCAT(r.HID, ROW_NUMBER()OVER(ORDER BY @@SPID), '/') as varchar(8000))

FROM dbo.ItemComponents ic

JOIN tree r ON ic.itmID = r.CompItmID

WHERE r.IsCycle = 0

)

INSERT INTO dbo.OrderBOMs

SELECT

bomID = 1

,itmID = t.CompItmID

,itmIDParent = t.itmID

,t.HIDPath

,t.HID

,t.itmcQty

,t.itmcQtyExt

FROM tree t

-- show our tree indented

SELECT

itmItemNumber = SPACE(bom.HID.GetLevel() * 4) + itm.itmItemNumber

,bom.itmcQtyExt

,bom.itmcQty

,HIDPath = bom.HIDPath.ToString()

,HID = bom.HID.ToString()

,BOMLevel = bom.HID.GetLevel()

--,bom.itmID

--,bom.itmIDParent

FROM dbo.OrderBOMs bom

JOIN dbo.Items itm ON itm.itmID = bom.itmID

ORDER BY bom.HID

-- cost rollup process

DECLARE @Costs TABLE -- temporary stack for cost rollup

(

bomID int NOT NULL

,itmID int NOT NULL

,IsProcessed bit NOT NULL

,HID hierarchyid NOT NULL

,itmcQty decimal(9,4) NOT NULL

,itmcQtyExt decimal(9,4) NOT NULL

,BOMLevel smallint NOT NULL

,Material decimal(19,4) NOT NULL

,Labor decimal(19,4) NOT NULL

PRIMARY KEY CLUSTERED (HID ASC)

)

INSERT INTO @Costs

SELECT

bom.bomID

,bom.itmID

,IsProcessed = 0

,bom.HID

,bom.itmcQty

,bom.itmcQtyExt

,BOMLevel = bom.HID.GetLevel()

,Material = ISNULL(c.itmMaterial, 0)

,Labor = ISNULL(c.itmLabor, 0)

FROM dbo.OrderBOMs bom

LEFT JOIN dbo.ItemCosts c ON c.itmID = bom.itmID

DECLARE @Level_max smallint = 0, @rows int = 0, @bomID int = 1

-- tag leaf level parts and discover tree depth

UPDATE t

SET t.IsProcessed = 1

,@Level_max = CASE WHEN t.BOMLevel > @Level_max THEN t.BOMLevel ELSE @Level_max END -- discover max BOM level while updating

OUTPUT SPACE(inserted.HID.GetLevel() * 4) + itm.itmItemNumber as itmItemNumber, inserted.HID.ToString() as HID, inserted.Material as [inserted.Material], deleted.Material as [deleted.Material], inserted.Labor as [inserted.Labor], deleted.Labor as [deleted.Labor], CONCAT('Leaf level update: ', QUOTENAME(inserted.HID.GetLevel())) as [Action]

FROM @Costs t -- parent set

LEFT JOIN dbo.Items itm ON itm.itmID = t.itmID -- only needed to show human readable itmItemNumber

WHERE t.bomID = @bomID

AND NOT EXISTS -- have no other components, i.e. leaf level items

(

SELECT 1

FROM @Costs t_leaf

WHERE t_leaf.bomID = t.bomID

AND t_leaf.HID.GetAncestor(1) = t.HID

)

SET @rows = @@ROWCOUNT

SET @Level_max -= 1 -- decrement for the above updated level

WHILE @Level_max >= 0 AND @rows > 0

BEGIN

UPDATE t -- rollup to the parent component costs. tree needs to be iterated from bottom up. thus "cost rollup".

SET t.IsProcessed = 1

,t.Material = ISNULL(s.Material, 0)

,t.Labor += ISNULL(s.Labor, 0)

OUTPUT SPACE(inserted.HID.GetLevel() * 4) + itm.itmItemNumber as itmItemNumber, inserted.HID.ToString() as HID, inserted.Material as [inserted.Material], deleted.Material as [deleted.Material], inserted.Labor as [inserted.Labor], deleted.Labor as [deleted.Labor], 'update for level:' + QUOTENAME(@Level_max) as [Action]

FROM @Costs t

LEFT JOIN dbo.Items itm ON itm.itmID = t.itmID

OUTER APPLY

(

SELECT

SUM(t2.Material * t2.itmcQty ) as Material

,SUM(t2.Labor * t2.itmcQty) as Labor

FROM @Costs t2

WHERE t2.bomID = t.bomID

AND t2.HID.GetAncestor(1) = t.HID

) s

WHERE t.IsProcessed = 0

AND t.BOMLevel = @Level_max

SET @rows = @@ROWCOUNT

SET @Level_max -= 1

END

SELECT

itmItemNumber = SPACE(bom.HID.GetLevel() * 4) + itm.itmItemNumber

,bom.itmcQty

,bom.itmcQtyExt

,HIDPath = bom.HID.ToString()

,uc.itmMaterial

,uc.itmLabor

,c.Material

,c.Labor

,cc.Cost

,TotalCost = CAST(cc.Cost * bom.itmcQtyExt as decimal(9, 4))

FROM dbo.OrderBOMs bom

JOIN dbo.Items itm ON itm.itmID = bom.itmID

LEFT JOIN dbo.ItemCosts uc ON uc.itmID = bom.itmID

LEFT JOIN @Costs c ON c.bomID = bom.bomID AND c.HID = bom.HID

CROSS APPLY(SELECT Cost = CAST(c.Material + c.Labor as decimal(9, 4))) cc

WHERE bom.bomID = @bomID

ORDER BY bom.HID

IF @@TRANCOUNT > 0 ROLLBACK TRANSACTION

I use hierarchyid here, but parent/child relation can be used too. hierarchyid simplifies it for me. hierarchyid is hidden treasure in SQL Server.

Cost computation can depend on type of company, type of manufacturing, costing methods used, and many other factors.

Just to give you an example, here is an image showing cost rollup results in our ERP system for this unit.

![167531-2022-01-22-22-18-22-unit.jpg][2]

![167440-2022-01-22-22-16-23-costing.jpg][2]

Note how many cost elements are being processed as well as cost runs, which are compared to each other.

Those need to be separated as they hit different GL accounts in the financial system and get computed at various stages of manufacturing processes.

Any time tree node is changed, cost is recomputed on the fly, instantly, in multi-statement table-valued function at the core. I wrote all backend code.

Cost rollup cannot be done with recursive CTE as SQL Server does not support aggregation in iterative part of CTE, and direction needs to be from tree leaves to the top

At least I cannot see how it can be done.

I hope this demonstrates the process and helps in your quest.

Thanks

Vladimir [2]: /api/attachments/167531-2022-01-22-22-18-22-unit.jpg?platform=QnA [2]: /api/attachments/167440-2022-01-22-22-16-23-costing.jpg?platform=QnA