Note

Access to this page requires authorization. You can try signing in or changing directories.

Access to this page requires authorization. You can try changing directories.

You can use Returns Management to enter, set up, and maintain your Return Materials Authorization (RMA) and Return To Vendor (RTV) documents. If Returns Management is integrated with Service Call Management, an RMA is created automatically from a returnable parts line on a service call. If Returns Management is integrated with Sales Order Processing, you can select items directly from the historical Sales Order Processing invoice that was generated for a specific customer.

The introduction is divided into the following topics:

• What’s in this manual

• Symbols and conventions

• Resources available from the Help menu

• Send us your documentation comments

What’s in this manual

This manual is designed to give you an understanding of how to use the features of Returns Management, and how it integrates with the Microsoft Dynamics® GP system.

Some features described in the documentation are optional and can be purchased through your Microsoft Dynamics GP partner.

To view information about the release of Microsoft Dynamics GP that you’re using and which modules or features you are registered to use, choose Help > About Microsoft Dynamics GP.

The manual is divided into the following parts:

Part 1, Returns Management setup, introduces Returns Management and explains its setup.

Part 2, Transaction activity, explains how to enter RMA and RTV documents. It also explains how to receive, ship, and close these return documents. Additional processes, such as reconciling inventory quantities and removing return document history, also are discussed.

Part 3, Inquiries and reports, explains how to use inquiries and reports to analyze your item return information.

Part 1: Returns Management setup

When you set up Returns Management, you can select options, set up and customize Return Materials Authorization (RMA) and Return to Vendor (RTV) document types, and specify how default entries are displayed when you enter transactions.

Setup procedures generally need to be completed only once, but you may want to refer to this information for instructions on modifying or viewing existing entries. The following topics are discussed:

Chapter 1, “Setup overview,” describes the various document types found in Returns Management and how to use the Setup Checklist to assist in setting up Returns Management.

Chapter 2, “Setup in Returns Management,” explains how to set up Returns Management and each document type within Returns Management.

Chapter 1: Setup overview

Use Returns Management to enter, receive, ship, and process item returns. You can use Returns Management for both the customer side of your returns process, as well as sending items back to your vendors to complete the entire return life cycle for an item.

This information is divided into the following topics:

Before setting up Returns Management

Use the Setup Checklist

RMA life cycle

RMA types

RTV life cycle

RTV types

Before setting up Returns Management

Before setting up Returns Management, complete the setup procedures for Sales Order Processing, Receivables Management, Inventory, and General Ledger, including the following tasks:

Create general ledger accounts for sales returns, cost of goods sold (COGS), scrap, repair sales, and reimbursements.

Enter customer records, including default general ledger accounts.

Enter inventory cards for items that will be sold and, potentially, returned by customers. You also should set up miscellaneous items for fees such as repair charges or restocking fees.

Create order, invoice, and return document types in Sales Order Processing.

For more information, see the System Setup Guide (Help > Printable Manuals) or the General Ledger, Receivables Management, Sales Order Processing, and Inventory Control documentation.

If you’re using Returns Management with Multicurrency Management, be sure you’ve set up currencies, exchange rate tables, and Multicurrency default entries. For more information, see the Multicurrency Management documentation.

Use the Setup Checklist

When setting up Returns Management, either open each setup window and enter information, or use the Setup Checklist window (Microsoft Dynamics GP menu > Tools > Setup > Setup Checklist) as a guide. See the System Setup Guide (Help > Printable Manuals) for more information.

RMA life cycle

When operating a returns warehouse, you sometimes interact with customers who need to return equipment for various reasons. When they bring you a part, you complete one of a few tasks: issue a credit, repair and return the item to the customer, or replace the item. You also may be accepting the item in exchange for an item you already provided to the customer. Once you’ve completed your transaction with the customer, you have a few more options: repair the item and return it to your inventory, return the item to the vendor, or scrap the item.

The following diagram outlines the life cycle of Return Materials Authorizations (RMAs), from entry through completion. When Returns Management is integrated with the other modules of the Field Service Series (Service Call Management, Preventive Maintenance, Contract Administration, and Depot Management), many new options and paths become available.

IMAGE – FARM1.jpg

A close up of a logo Description automatically generated

You can create RMAs from two different points of access throughout Field Service:

Manual entry in the RMA Entry/Update window

From return lines for returnable items on a service call

Entry in the RMA Entry/Update window is the method described in this manual. Refer to the Service Call Management documentation for more information regarding service calls and returnable items.

RMA types

RMA documents are used to track an item return from your customers. The available RMA document types are as follows:

Credit Provide a credit to your customer’s account in Receivables Management for the value of the items the customer returned to you.

Replacement Provide the same item, or a similar item, as a replacement to your customer. You must receive the original item from your customer before you send the replacement item on a new order document in Sales Order Processing.

Advance Cross–ship Provide the same item, or a similar item, as a replacement to your customer. You can send the replacement item using a new Sales Order Processing order document prior to receiving the original item from your customer.

Repair and Return You, or your vendor, will repair the item that is received from the customer. Your customer will receive the item after it’s been repaired.

None The customer’s original item is picked up by your field service technician and returned to your returns warehouse. This type of RMA document was designed to integrate directly with Service Call Management.

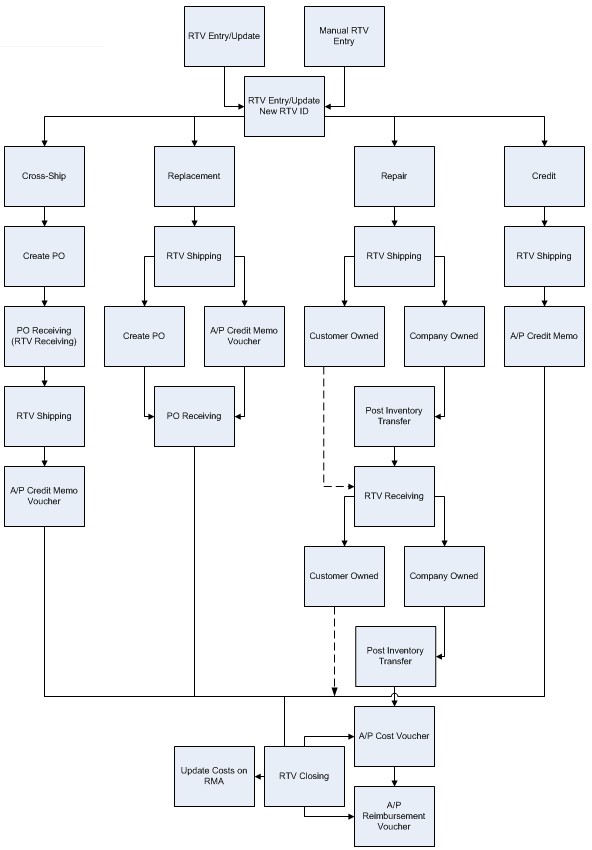

RTV life cycle

With RTVs, you become the customer, and the vendor takes your place in the scenario. You bring your vendor a part and your vendor completes one of a few tasks: issues a credit, repairs and returns the item to you, or replaces the item. You also may be returning an item in exchange for an item you already were provided. You can return the item to your customer or to your inventory.

The following diagram outlines the major points of interest for users of Returns Management who are entering RTVs. From entry through completion, the greater stages of the RTV document life cycle are covered. When Returns Management is integrated with the other modules of the Field Service Series (Service Call Management, Preventive Maintenance, Contract Administration, and Depot Management), many new options and paths become available.

IMAGE – FARM2.jpg

A screenshot of a cell phone Description automatically generated

You can create RTVs from two different points of access throughout the Field Service Series:

Manual entry in the RTV Entry/Update window

Automatically generated with the Create button in the RMA Line Process Return window, where the process type is set to Create RTV.

RTV types

RTV documents are used to track items that are sent back to your vendors. Returns Management supports four different methods of accounting for returns to fit your business needs.

Credit You receive a credit against your vendor’s account in Accounts Payable for the value of the items that you returned.

Replacement Your vendor ships you the same, or a similar, item as a replacement. The shipment of the original item to the vendor generates a purchase order, that the replacement item will be received against.

Advance Cross–ship Your vendor ships you the same, or a similar, item as a replacement. A purchase order is created immediately so that the replacement item can be received before the vendor receives the original item that you are returning.

Repair and Return Your vendor has agreed to take the item and repair it. You will receive the same repaired item back from the vendor at the end of the repair process. This type is not available for non-inventoried items.

Chapter 2: Setup in Returns Management

Returns Management setup involves setting up preferences such as data entry default entries and vendor reimbursement amounts, as well as Sales Order Processing document types used for replacement shipments and miscellaneous fees.

When you set up Returns Management, you can open each window and enter information or you can follow the Setup Checklist, which you can use as a guide to the setup process. For more information, see Use the Setup Checklist.

This information is divided into the following topics:

Set up options and default entries

Set up return document security

Set up RMA status codes

Set up RMA types

Set up RMA reason codes

Returned items

Set up RTV status codes

Set up RTV types

Set up vendor extensions

Set up reimbursements

Set up item extensions

Set up customer extensions

Set up warranties

Set up equipment maintenance cards

Set up options and default entries

You can set up default entries and other information that will affect the return documents that you will enter. You also can set up security options for return documents.

To accelerate the transaction entry process, specify common entries that will appear automatically when you enter return documents.

Vendor Validation is the process that Returns Management uses when processing RTVs to verify the suitability of a vendor for returning items. Vendors that are assigned to a given item number in inventory are verified automatically.

- Open the Service Setup – Returns window. Microsoft Dynamics GP menu > Tools > Setup > Project > Service Setup > Return button

A screenshot of a cell phone Description automatically generated

- Specify the RMA default settings.

Default RMA Type The RMA type for creating new RMAs.

Credit Batch ID The SOP Batch ID for SOP returns that are created from the RMA credit, replacement, and cross–ship type processes. You can post the documents to unique batches according to the RMA type.

Order Batch ID The SOP Batch ID for SOP Order documents that are created by the RMA receiving process or from the replace and cross–ship functions. You can post the documents to unique batches according to the RMA type.

Invoice Batch ID The SOP Invoice Batch ID for SOP Invoice documents that are created by the RMA closing process. You can post the documents to unique batches according to the RMA type.

Enter the Next RMA Number, using only numeric values, so that the Next RMA Number is incremented properly each time a new RMA document is created.

Select the options to include in the RMA life cycle.

Auto–Credit Receipts Returns Management automatically should create the Sales Order Processing (SOP) return document for Credit type RMAs when you post RMA Receivings.

Auto–Replace Receipts When a Replacement type RMA is received, the SOP return document is created automatically, as well as the SOP order document for the replacement item.

Auto–CrossShip Receipts When a Cross–ship type RMA is received, the SOP return document is created automatically, as well as the SOP order document (unless it has already been created).

Allow $0.00 Invoices Permit the creation of invoices for net currency amounts of zero, even on closed RMA documents.

Create History Distribution Records Returns Management should create a History Distribution record automatically when the RMA is moved to history. If cleared, the distribution records will not be available for inquiry on history records.

Enter up to five fields of your choice for special RMA functions that are not available elsewhere in Field Service.

Specify the RTV default settings.

Default RTV Type The RTV type for creating new RTVs.

Vendor Site ID The “via” (or intransit) site on the inventory transfer for a repair and return type RTV.

If a Site ID isn’t set up in the Vendor Extensions window, the Vendor Site ID specified in the setup window is the default Intransit/Via site for inventory transfers for repair and return RTVs. For example, you might have specific site IDs set up in Vendor Extensions for the vendors you deal with most often and a generic site ID for those vendors with whom you have less repair volume.

Enter the Next RTV Number, using only numeric values, so that the Next RTV Number is incremented properly each time a new RTV document is created.

Select one of four Vendor Validations that Returns Management will use when creating RTV records.

Full prompting A message is displayed when you save an RTV where the vendor isn’t assigned to the item being returned. You can click Yes to open the Item Vendors Maintenance window (Cards > Inventory > Vendors), where you will need to enter information regarding the item/vendor relationship and save the record.

Link with prompt A message is displayed when you save an RTV where the vendor isn’t assigned to the return item. You can click Yes, and the system will save the entry in the Item Vendors Maintenance window automatically.

Link without prompt No message is displayed if there isn’t a record for the item and the vendor in the Item Vendors Maintenance window. If the item vendor record doesn’t exist, one is created automatically and the item number is assigned as the vendor item number.

Existing vendors only Vendors can’t be added to items if they aren’t already assigned to the item.

- Select the options to include in your RTV life cycle.

Create History Distribution Records A History Distribution record should be created automatically when the RTV is moved to history. If cleared, the distribution records will not be available for inquiry on history records.

Enable RTV Supersession Posts a supersession to the Equipment Master record when a different inbound item number or serial number is received from Purchase Receiving or RTV Receiving. Supersessions allow you to transfer items from one serial record to another, one item to another, one item number to another, or one reference ID to another.

Enter up to five fields of your choice for special RTV functions that are not available elsewhere in Field Service.

Click Options to specify document security settings.

Click OK.

Set up return document security

Because RMA and RTV documents can be deleted or voided in the Entry/Update windows, your business processes might require that users be prevented from completing these actions. You can prevent users from deleting or voiding certain documents, while still allowing them access to the window to enter or update documents, by setting up passwords.

If you set up a password, users are required to enter the password before deleting or voiding the selected document type. If an option is selected, but a password hasn’t been set up, anyone who has access to the RMA Entry/Update window or the RTV Entry/Update window can delete or void the applicable document type.

Open the Option Security – Returns Management window. Microsoft Dynamics GP menu > Tools > Setup > Project > Service Setup > Return button > Options button

Select the document type that you’re setting up document security privileges for.

To remove the right for users to delete or void a particular document type, clear the Allow check box.

To use passwords, enter a password for each option.

Click OK.

Set up RMA status codes

You can create status codes that represent the life cycle of an RMA, from creation to closure. RMA status codes are assigned to RMA documents based on the completion of certain events, such as the posting of RMA receiving. The description you enter should provide a clear explanation of the RMA status.

Open the RMA Status Maintenance window. Cards > Returns Management > RMA Status

Enter an RMA Status ID and description.

Click Save.

Set up RMA types

Each RMA type represents a different way of handling a return for your customer, such as providing the customer credit on their account or replacing an item. Even within these customer return paths you could create multiple RMA types to handle different options, such as different Sales Order Processing document IDs. You can set up and customize an unlimited number of RMA types.

For example, you can use separate types of return documents for credit, replacement, cross–ship, or repair and return RMAs. Using the RMA Type Maintenance windows, you can set up each of these separate return types.

Only one return path can be applied to each RMA type. The customer path that you select for an RMA type determines the Customer Path button that is enabled in the RMA Entry/Update window for a new RMA document.

After you’ve set up at least one RMA type, you can complete the setup of common entries in the RMA Entry/Update windows.

- Open the RMA Type Maintenance window. Cards > Returns Management > RMA Types

IMAGE – FARM4.jpg

A screenshot of a cell phone Description automatically generated

Enter an RMA Type ID and a description.

Enter default RMA status codes for the RMA type, which represent each phase listed in the RMA life cycle.

Entered Status The code that appears in the RMA Status field when you click New in the RMA Entry/Update window.

Partially Received Status The code that appears when some, but not all, of the line items on an RMA document have been received. Once you locate a line item in the RMA Receiving window and post it, the status of the RMA itself will change to Partially Received Status if there are other line items that have not been received yet.

Received Status The code that appears once the returned item was received at the return location. Once you locate the RMA ID in the RMA Receiving window and post it, the status will change to the Received Status code assigned to the RMA type.

Discrepancy Status The code that appears if the customer returned something different than what you expected to receive.

During the RMA receiving process, you may change the returned item number, returned serial number, or returned quantity. If any of these values are different from the original data on the RMA, the RMA is flagged as a discrepancy. At the end of the receiving process, a discrepancy report is printed and those RMAs have their status set to the Discrepancy Status instead of the Received Status. Someone in your organization may then verify or review the RMAs that have a discrepancy status.

WO Status The code that appears when the repair of the returned item was completed within Depot Management.

Ready To Close Status The code that appears when an individual RMA line item has been received and is now ready to be closed. Each RMA line item is selected as Ready to Close when you click the Ready Close button in the RMA Entry window.

Closed Status The code that appears when the RMA is in the final stage for a completed return. Once you locate the RMA ID in the RMA Closing window and post it, the status will change automatically to the Closed status code assigned to the RMA type.

Enter or select a default intransit location for any inventory transfer that is generated when you process a return that is using the RMA type.

Enter or select a default return location that is designated as the site where the item will be received.

Select a customer path, which indicates the action required on the customer’s behalf once the return has been created.

None If selected, no further action is required on behalf of the customer.

Repair & Return If selected, you need to repair an item and return the same item to the customer.

Credit If selected, you need to issue a credit instead of a replacement part to the customer for this RMA type.

Replacement If selected, you need to replace the returned item with the same type of item or another substitute item and issue a credit to the customer for the value of the returned item.

Advanced Cross–Ship If selected, you need to send a replacement item to the customer before you receive the returned item back from the customer.

Define different document IDs for customer credits, replacement orders, and the invoices that can be created during RMA closing.

Assign different batch IDs for each type of RMA to allow more flexibility in posting Sales Order Processing batches for customer credits, replacement orders, and invoices for additional charges. The default batch IDs are defined in the Service Returns Setup window.

Click Accounts to enter default general ledger posting accounts to be used for various RMA distribution accounts. If these accounts are left blank in the RMA Type Accounts window, the posting accounts are pulled from other locations such as item cards or posting account setup.

Click Save.

Set up RMA reason codes

You can create unique reason codes that describe the purpose for the customer return.

RMA reason codes can be attached directly to an RMA document or, if you are using Service Call Management, to a Service Call Returned line. The reason code also follow the item to a Depot Work Order if you are using Depot Management.

Open the RMA Reason Code Maintenance window. Cards > Returns Management > RMA Reason Code

Enter an RMA Reason Code and description.

Click Save.

Returned items

RMA from a service call parts return line

When creating an RMA document from a service call, the return item cost established in the Item Extensions window will be used for both the return line and the RMA returned item cost. The returned item cost will appear on the inventory adjustment posting.

RMA from a sales invoice

When entering an RMA with a SOP invoice as the origin, the returned item cost is the cost of the item from the original invoice. You can override the original cost by manually entering the new cost. The RMA cost is posted during the receiving process and also will appear on the RMA credit voucher. If a new SOP order is created during the RMA life cycle, then the cost of the item is used on the new invoice.

RMA with no origin document

If you are entering an RMA with no origin, the RMA uses the cost based on the information specified on the Item Extension card.

Set up RTV status codes

The RTV status is a unique code used to represent the status that an RTV may achieve, from an entered to a closed RTV.

Open the RTV Status Maintenance window. Cards > Returns Management > RTV Status

Enter an RTV Status ID and description.

Click Save.

Set up RTV types

You can set up and customize an unlimited number of RTV types. For example, you can use separate types of return documents for credit, replacement, cross–ship, or repair and return RTVs. Each RTV type represents one of these return paths offered by your vendors. Even within each of the vendors’ return paths, you might have additional RTV types, each of which has a different set of return status codes or different general ledger default accounts.

Only one return path can be applied to each RTV type. The return path that you select for each RTV type in the RTV Type Maintenance window will dictate which Return Path button is active when you create an RTV in the RTV Entry/Update window.

After you’ve set up at least one RTV type, you can complete the setup of common entries in the RTV Entry/Update windows.

Open the RTV Type Maintenance window. Cards > Returns Management > RTV Types

Enter an RTV type and description.

Enter or select RTV status codes for the RTV type, which represent each phase listed in the RTV life cycle.

Entered Status The code that appears in the RTV Status field when you click New in the RTV Entry/Update window.

Ready To Ship Status The code that appears when the returned item is ready to be shipped to the vendor, but has not left the location.

Partially Shipped Status The code that appears when some, but not all, of the returned item has been shipped.

Shipped Status The code that appears when the entire returned item has been shipped from your location and is in transit to the vendor.

Partially Received Status The code that appears when some, but not all, of the return item was received at the vendor location.

Received Status The code that appears once the returned item has been received at your return location.

Closed Status The code that appears when the RTV is in the final stage for a completed return.

Enter or select the sending location, which is the default site ID that the returned item is being sent from. This would normally be the returns location, and is displayed as the Outbound Site on the RTV.

Enter or select the return location, which is the default site ID designated for the item’s return for this RTV type. This is displayed as the inbound site on the RTV.

Select a return path, which indicates the final disposition of the returned item.

Credit Indicates that you will receive a credit from your vendor for the item you’re returning.

Replacement Indicates that your vendor will replace the returned item with the same item or another substitute item.

Advanced Cross Ship Indicates that your vendor will ship a replacement item to you before your vendor receives the returned item from you.

Repair & Return Indicates that your vendor will repair and return the item to you.

Click Accounts to specify the default accounts to be used as various general ledger distributions on RTV documents.

Click Save.

Set up vendor extensions

You can identify a specific site ID for a vendor location when you process Repair and Return RTVs.

Because the items will be returned to you after they are repaired, they still will be accounted for in your inventory. You might have several “vendor” sites to assist you in quickly identifying the items and quantities that are at a vendor for repair. For example, you might have specific site IDs for your most common repair vendors and a generic VENDOR site ID for those vendors with less repair volume. If no entry is made in Vendor Extensions, the default site ID from the Service Setup – Returns window is used for all vendors.

Open the Vendor Ext Maintenance window. Cards > Returns Management > Vendor Extensions

Enter or select the Vendor ID of the vendor that the return items will be sent to.

Enter the address where the return items will be shipped to.

Enter the site where the vendor will repair the return items. The site ID is the default “via” site on the transfer for a repair and return RTV.

Select the Default Site option when a vendor has multiple address IDs to indicate which site is the default site for repairs.

Click Save.

Set up reimbursements

Reimbursement values are the amounts or percentages the vendor has agreed to reimburse your company for charges you might have incurred for a defective item or some other problem related to the RTV.

The values in the Reimbursement Maintenance window are the default entries for RTVs in the RTV Entry/Update window. While default currency amounts appear on RTVs, percentages are entered only for informational use and won’t be used in the creation of the Payables Management credit document.

During the RTV closing process, the currency values in the reimbursement fields on the RTV are totaled and a credit voucher is created in Payables Management for that currency amount.

Open the Reimbursement Maintenance window. Cards > Returns Management > Reimbursement

Enter or accept the default Vendor ID that your company has a reimbursement agreement with.

Enter or accept the default Item Number that normally is returned to the vendor specified.

Enter or select the RTV Type that represents the type of return work that your company is reimbursed for.

Enter an A (Amount) or P (Percentage) that the vendor will reimburse you for each line type.

Enter the Not to Exceed Value for each line type for informational use.

Click Save.

Set up item extensions

You can assign, modify, or delete additional item information that is not available in Inventory Control. For example, certain items might be returnable or track meter usage; this information isn’t tracked within Inventory Control, but is important for service situations.

The vendor warranty code that you select is used when entering new items in the Equipment Maintenance window. The seller warranty code that you select represents the warranty your company offers to your customer. This information is used when an equipment master record is created.

The MTBF (Mean Time Between Failure), the MTBI (Mean Time Between Incidents), and the MTTR (Mean Time To Repair) are estimates that can be recorded for the item as additional information.

The returned item cost will affect three different situations: Service Call R–Line, Depot Work Order Completion, and Return Item cost when an RMA is created with no source document. For more information, see Returned items.

Open the Item Extensions window. Cards > Service Call Management > Extensions > Item or Cards > Inventory > Item > Additional > Service Extensions

Enter item information. For more information, see Set up item extensions of the Service Call Management manual.

Click Save.

Set up customer extensions

You can create, modify, or delete additional customer information that isn’t available in Receivables Management. You also can enter the default time zone, office hours, service area, and other information that may be used when servicing the customer account.

The Bill to Customer information in the Customer Extensions window is entered automatically on a service call when the customer ID and address ID on a service call match an existing customer extension record.

The date in the Last Service Date field is when service work was most recently performed for the customer location. This date is updated each time a service call is invoiced for the current customer and site combination.

Open the Customer Extensions window. Cards > Service Call Management > Extensions > Customer or Cards > Sales > Addresses > Select a customer and an address ID > Additional > Service Extensions

Enter customer information. For more information, see Set up customer extensions of the Service Call Management manual.

Click Save.

IMAGE – FARM6.jpg

A screenshot of a cell phone Description automatically generated

Set up warranties

You can define codes that represent the different types of warranties offered to your customers. These warranty codes may represent the original manufacturer’s warranty or your own warranty on equipment serviced and/or sold by your company.

Open the Warranty Maintenance window. Cards > Service Call Management > Warranty

Enter warranty information. For more information, see Set up warranties of the Service Call Management manual.

Click Save.

IMAGE – FARM7.jpg

A screenshot of a cell phone Description automatically generated

Set up equipment maintenance cards

You can create a record for any specifically identifiable equipment within your customer–installed base. All the information you need for this equipment, including the customer who owns the equipment, the location of the equipment, and warranty information, can be found in the Equipment Maintenance window.

The equipment record can be created automatically when you receive an item in Purchase Order Processing, when you sell an item with a serial number in Sales Order Processing, or when a new item with a serial number is added to a service call in Service Call Entry/Update.

In order for an equipment record to be created from Purchase Order Processing, the Create Equipment from POP option must be selected in Service Setup.

To create an equipment record from Sales Order Processing, you must select the

Create Equipment from SOP option in Service Setup. During the Sales Order Processing posting process, the equipment card is created for any items with a serial number on an invoice document.

The Quantity field is only available for equipment items that do not have serial numbers and allows you to track multiple quantities of the equipment.

You can change the address information if necessary to record a more exact location for the equipment.

In the navigation pane, choose the Field Service button, and then choose the Equipment list.

Choose the New Equipment button to display the Equipment Maintenance window.

Enter equipment information. For more details, see Set up equipment maintenance cards of the Contract Administration manual.

Click Save.

IMAGE – FARM8.jpg

A screenshot of a social media post Description automatically generated

Part 2: Transaction activity

Use the procedures described in the following parts of the documentation to enter RMA (Return Materials Authorization) and RTV (Return To Vendor) documents, as well as to complete standard return entries within Returns Management.

The following topics are discussed:

Chapter 3, “Routine procedures,” describes how to create return documents and complete other processes, such as copying existing RMA documents.

Chapter 4, “Posting procedures,” explains some of the posting processes that take place within Returns Management, such as receiving an RMA or closing an RTV.

Chapter 5, “Maintenance procedures,” describes processes that affect the performance of your returns system, such as reconciling inventory quantities and removing historical records.

Chapter 3: Routine procedures

Processing customer and vendor returns is a common routine in many businesses. RMAs and RTVs can be saved, modified if necessary, and then completed so your customers and your vendors can get the necessary information they need.

The RMA Entry/Update window is a multipurpose window used for entering and printing RMA and RTV information. You also can view, update, void, copy, or delete existing RMAs and RTVs.

The RMA and RTV windows were designed to mirror the actual return process within a typical organization, with functions such as the entry of RMA documents separated from those of other users. You can enter and save RMAs and RTVs, as well as complete any shipping and necessary receiving of the items on these documents.

This information is divided into the following topics:

Enter a credit RMA

Enter a replacement RMA

Enter a cross–ship RMA

Enter a repair and return RMA

Copy an RMA

Create an internal RMA

Create an RTV from an RMA

Create a depot work order from an RMA

Scrap an item from an RMA

Void an RMA

RMA entry details

Enter a credit RTV

Enter a replacement RTV

Enter a cross–ship RTV

Enter a repair and return RTV

Void an RTV

RTV entry details

Enter a credit RMA

You should use credit RMA documents when a customer returns an item for a credit on their account for any remaining value, rather then having the item repaired or replaced.

The bill–to information is used to determine which customer will be on the Sales Order Processing return documents for this RMA. You can change this to a different customer, address, or customer and address combination, if necessary. The bill–to customer will be the same as the customer ID unless a default bill–to customer was specified in Customer Extensions.

The returned line uses the item cost specified on the Item Extension card to bring the item back into inventory. That cost transfers to the return site when the RMA is received in RMA Receiving.

When an RMA is created manually in the RMA Entry/Update window and the

Origin is set to Service Call, a list of all invoiced service calls will appear. Select the

service call that contains the item to be returned. You can view all items or serial numbers from the selected service call with a line item type of Installed.

In the navigation pane, choose the Field Service button, and then choose the RMA Transactions list.

Choose the RMA button to display the RMA Entry/Update window.

Enter or select an RMA Number to modify an existing RMA or click New to generate the next default RMA number.

Select an RMA Type that is set for credit. For more information about RMA types, see Set up RMA types.

Enter or select an RMA Status and RMA Reason Code.

Enter or select customer information.

Select the origin of the return.

Service Call If you are using Service Call Management and an item selected as Returnable in the Item Extensions window is entered in the Service Call Parts window, a returned line is created automatically. An RMA document is created automatically when the Quantity Sold value is entered on a returned line. The RMA Origin is set to Service Call automatically when the system creates that RMA document.

Sales Invoice If the source document for the customer’s return is a Sales Order Processing invoice, select Sales Invoice to view a list of available sales invoices that you can select the document number to be returned from. A sales invoice can be returned in full, or specific line items and quantities can be returned. All of the default item information for the RMA come from the selected sales order lines. When entering an RMA that will use a SOP invoice as the origin, the default returned item cost is the cost of the item from the original invoice document. The RMA cost is used during the receiving process for the posted inventory transaction and also is passed to the SOP return document.

None If you are entering an RMA with no source document, select the default of None. The default RMA cost will be determined from the information specified on the extension card.

Enter or accept the default Office ID, where the item will be returned. You also can enter the Site ID for the current RMA document.

Enter or accept the default Currency ID.

Enter the customer’s purchase order number.

Enter or select the RMA Type, Item Number, U of M, Quantity, and Return Price of the item that the customer is returning.

- If a message about price levels appears and the Use Return Price Level option is selected in the Return Setup window, be sure that the item is set up to use the specified return price level.

Enter additional line items if necessary.

Click the line item expansion button to enter additional information for the selected RMA line item.

Click the Link icon next to the Customer Path to enter additional information related to the RMA line item.

If the line item is a kit item, click the Kits button to view or modify information for the kit components.

If your company uses multiple bins, click the Bins button to enter or verify the bin into which the returned item will be received.

Click Process to select the disposition of the items on the current RMA line item. Select options to send quantities to RTV documents or to a depot work order, or scrap them from inventory. If the current RMA line item contains multiple quantities or serial numbers, you can separate them to different dispositions. The Process button is not available for kit items. You can use the Process button in the RMA – Kit Components window to specify the disposition of kit components.

Click Create to generate the selected document. For more information, see Create an RTV from an RMA, Create a depot work order from an RMA, or Scrap an item from an RMA.

Click Serial to enter or verify the serial numbers assigned to the current RMA line. The serial numbers received must match the quantity that was entered on the current line item.

Click User–Defined to enter additional information for the current RMA line item. You can enter up to five user–defined fields per line item.

If the current RMA line item has an inventory transfer associated with it, you can view that transfer document by clicking Transfer.

Click Distribution to view posted and unposted General Ledger distribution accounts associated with the current RMA line item.

To scroll between RMA line items, click the Previous or Next scroll buttons at the bottom of the detailed window.

Click the RMA Number expansion button to enter user–defined information for the entire RMA document. Then, click Distribution to view or modify the default general ledger distribution account information for the entire RMA transaction.

Click Save.

IMAGE – FARM9.jpg

A screenshot of a cell phone Description automatically generated

Enter a replacement RMA

You should use replacement RMA documents when a customer returns a piece of equipment, and your company needs to provide them a replacement item for the returned item.

In the navigation pane, choose the Field Service button, and then choose the RMA Transactions list.

Choose the RMA button to display the RMA Entry/Update window.

Enter an RMA Number or click New to generate the next default RMA number.

Select an RMA Type that is set for replacement. For more information, see Set up RMA types.

Enter an RMA Status and RMA Reason Code.

Enter or select customer information.

Enter additional line item information if necessary. For more detailed information about this window’s information, see Enter a credit RMA.

Click Save.

Enter a cross–ship RMA

You should use cross–ship RMA documents when a customer is going to return an item that their business cannot function without, and your company needs to provide a new replacement item before you receive the return equipment.

In the navigation pane, choose the Field Service button, and then choose the RMA Transactions list.

Choose the RMA button to display the RMA Entry/Update window.

Enter an RMA Number or click New to generate the next default RMA number.

Select an RMA Type that is set for cross–ship. For more information, see Set up RMA types.

Enter an RMA Status and RMA Reason Code.

Enter or select customer information.

Enter additional line item information if necessary. For more detailed information about this window’s information, see Enter a credit RMA.

Click Save.

Enter a repair and return RMA

You should use repair RMA documents when a customer is going to return an item, and your company needs to repair the item and send that same item back to the customer.

In the navigation pane, choose the Field Service button, and then choose the RMA Transactions list.

Choose the RMA button to display the RMA Entry/Update window.

Enter an RMA Number or click New to generate the next default RMA number.

Select an RMA Type that is set for repair and return. For more information, see Set up RMA types.

Enter an RMA Status and RMA Reason Code.

Enter or select customer information.

Enter additional line item information if necessary. For more detailed information about this window’s information, see Enter a credit RMA.

Click Save.

Copy an RMA

You can copy current RMA information to a new RMA.

Open the RMA Entry/Update window. Transactions > Returns Management > RMA Entry/Update

Click the RMA number lookup button and select an RMA. Click Select.

Click Copy to copy all the main RMA and RMA line information exactly as it is to a new RMA document.

Create an internal RMA

You can create RMAs and transfers for items that are already in your inventory. The Internal RMA window was designed to assist users in creating RMAs for stock that already had been received into their warehouse but didn’t have an RMA associated with it. You can use this window to enter and post internal RMAs.

Because the RMA item is already in your company’s inventory, be sure that your company is set up as a customer ID so you can choose your company as the customer ID.

When you post the internal RMA, the RMA document is created and transferred to move the inventory into the “return” location specified in the RMA Internal Entry window. After the RMA is posted, you can then perform the normal RMA Receiving and processing procedures.

Open the Internal RMA Entry window. Transactions > Returns Management > RMA Internal Entry

Enter or select an RMA Type.

Enter or select an Office ID.

Enter or select the Return Site, which will be the default location designated for the item’s return.

Enter or accept the default Customer ID.

Enter or select the Item Number to be used on the current record.

Enter the current Site ID for the item.

Enter the quantity of the item that needs to be returned. The inventory must be available in the site to enter the quantity.

Click Serial/Lot to look up serial or lot numbers that are available for that item site and attach them to the transfer that is created when the Internal RMA is posted.

To enter information that further identifies the item, enter it in the Reference field.

Click Post to attach the information in the current window to an RMA document and create an inventory transfer to move the items from the site ID to the return site.

Create an RTV from an RMA

You can specify the disposition of the item your customer has returned to you. If you decide to send the item back to your vendor, an RTV document will be created.

Each RTV is created for a specific vendor and can have multiple items on it if each item is for the same vendor. For instance, if you process four different RMA lines to create an RTV and the items are all from the same vendor, the RTV will have four lines, all using the information from the RMA. An RTV can be sourced from only one RMA number.

If an RMA has three items from three different vendors, one RTV will be created for each vendor.

Open the RMA Entry/Update window. Transactions > Returns Management > RMA Entry/Update

Select the RMA line item that you want to work with and select the ‘show detail’ button.

Click the Process button to choose the disposition of the item.

If you decide to send the returned part back to the vendor, select Return to Vendor in the Process Type list, and click Create to generate the RTV document.

If the current RMA line item contains multiple serial numbers or multiple quantities and you do not process the entire quantity to the selected RTV document, a second process line will be generated for the remaining quantity.

A Create RTV All button will be available for multiple lines with serial information so that a single RTV can be created.

- Click Save.

Create a depot work order from an RMA

You can specify the disposition of the item your customer has returned to you. If you decide to send the item into your depot, or in–house repair facility, a depot work order will be created. You must be using Depot Management to access this option.

Open the RMA Entry/Update window. Transactions > Returns Management > RMA Entry/Update

Select the RMA line item from the ‘show detail’ button.

Click Process to choose the disposition of the item.

To send the returned part into your internal repair facility, select one of the work order options from the Process Type list

Click Create to generate a work order document.

- If the current RMA line item contains multiple serial numbers or multiple quantities and you do not process the entire quantity to the selected RTV document, a second process line will be generated for the remaining quantity.

Click the Document link to view work order information. The Status field displays the status of the depot work order.

Click Save.

Scrap an item from an RMA

If you decide that the item your customer has returned no longer has any value, you can scrap the item and it will be decreased out of your inventory.

The cost of the items without serial numbers that are scrapped is determined by the inventory “layer” that is relieved. If the item being scrapped is a high volume item and depending on the item’s inventory valuation method, the cost of the unit that is scrapped might differ from the RMA receiving cost.

Because items without serial numbers can be identified specifically in inventory, the rule above doesn’t apply. Each item with a serial number represents its own inventory “layer,” therefore its cost will follow it from receiving when it is scrapped.

Open the RMA Entry/Update window. Transactions > Returns Management > RMA Entry/Update

Select the RMA line item from the ‘show detail’ button.

Click Process to choose the disposition of the item.

Select the Inventory Scrap option from the Process Type list and click Create to generate the inventory scrap document and a decrease adjustment.

- If the current RMA line item contains multiple serial numbers or multiple quantities and you do not process the entire quantity to the selected scrap transaction, a second process line will be generated for the remaining quantity.

Click the Document field. The Status field displays the status of the inventory adjustment.

Click Save.

Void an RMA

Voiding return documents is different than deleting them because they are moved to history, so they remain in your records.

If an RMA has been received already, you can return the inventory to the customer or scrap the inventory. You also can print a Return document to give to the customer.

If the inventory is not owned by the customer, an inventory decrease adjustment will be posted.

The following conditions must be true before you can void an RMA:

The Void Documents option must be selected in the Option Security – Returns Management window.

The RMA was not created from a Service Call parts line.

Work Order document, RTVs, Inventory Scrap documents, and SOP documents don’t exist for the RMA line item. Any of these items can be voided manually.

Open the RMA Entry/Update window. Transactions > Returns Management > RMA Entry/Update

Enter or select the RMA number of the record that you want to void. The original information is displayed.

Click Void.

RMA entry details

When a user enters a repair price in the RMA Update Repair and Return window and leaves the Repair Price field, the distribution record is created with the default account numbers based on the following information:

This table is based on the Posting Accounts From option (Item or Customer) selected in the Sales Order Processing Setup window.

(Microsoft Dynamics GP menu > Tools > Setup > Sales > Sales Order Processing)

| Account | Location |

|---|---|

| Sales | Sales Returns account from Item Master record; if empty, then from Posting Accounts – Sales |

| Accounts Receivable | A/R account from Customer Master record; if empty, then from Posting Accounts – Sales |

When the RMA record is created manually, and the Origin selected is Service Call, the default account numbers from service type accounts (based on the service type assigned to the service call) are used, if not empty. The default account numbers from RMA type accounts are used if the Service Types Accounts are blank. When the RMA record is created and the Account Number in service type accounts and RMA type accounts are blank, the default account numbers are based on the following information.

This table is based on the Posting Accounts From option (Item or Customer) selected in the Sales Order Processing Setup window.

(Microsoft Dynamics GP menu > Tools > Setup > Sales > Sales Order Processing)

IMAGE – FARM10.jpg

A screenshot of a cell phone Description automatically generated

Enter a credit RTV

You should use credit RTV documents when your company returns an item to your vendor, who agrees to issue a credit on your account for the value of that item.

The RTV type you select determines the return path.

In the navigation pane, choose the Field Service button, and then choose the RTV Transactions list.

Choose the RTV button to display the RTV Entry/Update window.

Enter an RTV Number or click New to generate the next RTV number.

Select an RTV Type that is set for credit. For more information, see Set up RTV types.

Select or accept the default RTV Status. For more information, see Set up RTV status codes.

Enter or select an Office ID. If the RTV is created from an RMA, this field will be the default from the RMA.

Enter or select the Vendor ID and Address ID that the item will be sent to.

Click the Vendor Address ID expansion button to change shipping details.

Enter or accept the default Currency ID for the vendor.

In the scrolling (line detail) window, enter or select the following, and if necessary, change the Type field per RTV line.

Out–Site ID Where the return item is being sent from. You will need to have sufficient quantities of the item in this location before you will be able to ship the RTV.

Out–Item The outbound item number associated with the RTV.

In–Site ID Where the item will be returned to when received from the vendor.

In–Item The item number that will be returned to your inventory from the vendor.

U of M The appropriate unit of measure for each item.

Quantity The quantity of each item to be returned to the vendor.

Open the line detail window to specify additional information, such as the promised date and time, and cost and reimbursement amounts for each item.

Enter the Vendor Item Number. Then enter the Vendor RMA Number, which is the RMA number that the vendor has assigned to this return.

The entered, shipped, received, and closed dates and times are kept automatically. You can enter a date and time in the promised field to indicate the estimated date and time the item will be returned from the vendor.

If the return path that is highlighted isn’t Credit, choose an RTV type that is set up for Credit.

To issue or view a credit voucher, cost voucher, and reimbursement voucher that was created for the current RTV document, click the Credit button when it’s available.

The PO Number and PO Receiving Number fields aren’t used with credit RTVs.

View the credit voucher, which is created during the RTV shipping process.

View the cost voucher, if applicable. The creation of this voucher depends on whether you incur any costs for the return.

View the reimbursement voucher, if applicable. The creation of this voucher depends on whether you are owed any reimbursements from the vendor for the return.

Enter user data in Reference1 and Reference2 for informational use.

Enter any additional costs you will incur or reimbursements you will receive from your vendor.

If your company uses multiple bins, click Bins to specify the bin location of the item.

If the item specified is tracked with a serial or lot number, click the Serial/Lot button to specify the serial or lot numbers for each item. The serial or lot number quantity must match the quantity entered on the current line.

Click the User–Defined button to enter up to five values per RTV line.

Click Distribution to view the General Ledger distribution accounts associated with the current RTV line. You can view unposted and posted distributions.

To scroll between RTV line items, click the Previous or Next buttons.

Click Save.

Enter a replacement RTV

You should use replacement RTV documents when your company returns an item to your vendor, and your vendor agrees to replace it with a new item.

In the navigation pane, choose the Field Service button, and then choose the RTV Transactions list.

Choose the RTV button to display the RTV Entry/Update window.

Enter an RTV Number or click New to generate the next default RTV number.

Select an RTV Type that is set for replacement. For more information, see Set up RTV types.

Enter or select vendor information.

The RTV type you have chosen determines the return path. If the return path that is highlighted isn’t Replacement, choose a different RTV type that is set up for replacement.

To issue or view a credit voucher, cost voucher, and reimbursement voucher that was created for the current RTV document, click the Replacement button when it’s available.

Within the RTV Vouchers window, the PO number is generated during the RTV shipping and is the purchase order used to receive the replacement from the vendor.

The PO Receipt Number is updated by the Purchasing Receiving Post process.

View the credit voucher, if applicable. The creation of this voucher depends on whether you incur any costs for the return.

View the reimbursement voucher, if applicable. The creation of this voucher depends on whether you are owed any reimbursements from the vendor for the return.

Enter additional line item information if necessary. For more detailed information about this window’s information, see Enter a credit RTV.

Click Save.

Enter a cross–ship RTV

You should use cross–ship RTV documents when your company is going to return an item that your business cannot function without, and your vendor agrees to provide your company a new item in replacement before they will receive the return item.

In the navigation pane, choose the Field Service button, and then choose the RTV Transactions list.

Choose the RTV button to display the RTV Entry/Update window.

Enter an RTV Number or click New to generate the next default RTV number.

Select an RTV Type that is set for cross–ship. For more information, see Set up RTV types.

Enter or select vendor information.

The RTV type you have chosen determines the return path. If the return path that is highlighted isn’t Cross–ship, you will need to choose a different RTV type that is set up for Cross–ship.

To issue or view a credit voucher, cost voucher, and reimbursement voucher that was created for the current RTV document, use the Cross–ship button when it’s available. Use the Create PO button to create a purchase order for the RTV cross shipment.

Within the RTV Vouchers window, you can select the Consolidate PO option to combine return records with items going to the same vendor onto one purchase order document. For an item to be consolidated on an existing Purchase Order, the PO must meet the following criteria.

The PO Status must be “New.”

The PO must have the same vendor ID as the current RTV.

The PO number generated to receive the cross–shipped item is displayed.

The PO receipt number will be available after the Purchasing Receiving process has been completed for the cross–ship PO.

View the credit voucher, which is created during the RTV shipping process.

View the cost voucher, if applicable. The creation of this voucher depends on whether you incur any costs for the return.

View the reimbursement voucher, if applicable. The creation of this voucher depends on whether you are owed any reimbursements from the vendor for the return.

Enter additional line item information if necessary. For more detailed information about this window’s information, see Enter a credit RTV.

Click Save.

Enter a repair and return RTV

You should use repair RTV documents when your company returns an item to your vendor for repair. The vendor repairs the item and sends that same item back to your company.

In the navigation pane, choose the Field Service button, and then choose the RTV Transactions list.

Choose the RTV button to display the RTV Entry/Update window.

Enter an RTV Number or click New to generate the next default RTV number.

Select an RTV Type that is set for repair. For more information, see Set up RTV types.

Enter or select vendor information.

The RTV type you have chosen determines the return path. If the return path that is highlighted isn’t Repair, you will need to choose a different RTV type that is set up for Repair.

To create a transfer from the RTV sending location to the vendor site, and return to the return location, click the Repair button when it’s available. You can use this to show that the item is still in your inventory, but is at a vendor location being repaired.

You also can view a credit voucher, cost voucher, and reimbursement voucher. Click the Transfer button to place the RTV item on a transfer from one location to another. This will create a transfer document in the Inventory Transfer window. For more information, see Transfer inventory.

Within the RTV Vouchers window, you will see a Transfer Reference number. This is the transfer number that is generated when you click the Transfer button. You also can click it to open the In–Transit Transfer Entry window. The Transfer Line further identifies the transfer reference. If multiple lines are on the transfer, this will help you identify which item this transfer is referring to.

View the credit voucher, which is created during the RTV shipping process.

View the cost voucher, if applicable. The creation of this voucher depends on whether you incur any charges for the return.

View the reimbursement voucher, if applicable. The creation of this voucher depends on whether you are owed any reimbursements from the vendor for the return.

Enter additional line item information if necessary. For more detailed information about this window’s information, see Enter a credit RTV.

Click Save.

Void an RTV

Voiding return documents is different than deleting them because they are moved to history, so they remain in your records.

When you void a repair–type RTV that has been shipped and the related transfer is picked, you will unallocate the inventory. When you void a repair–type RTV that is ready to ship, you will unallocate the inventory specified on the related transfer.

Any closed lines on the RTV that you do not void are moved to the History tables. For example, if you void an RTV from an Open table, you will remove the Open RTV record and create a History RTV record.

The following conditions must exist before you can void an RTV.

The Void Documents option must be selected in the Option Security – Returns Management window.

All RTV line items are not in the process of being shipped through the RTV Shipping function.

Payables documents (Credit Voucher or Cost Voucher) cannot exist for the RTV line item. They can be voided manually.

Purchase Order documents don’t exist for the RTV line item. Any purchase orders can be voided manually

Any RTV that has a partial–received status or a received status cannot be voided.

Repair–type RTVs that are shipped cannot be voided.

Open the RTV Entry/Update window. Transactions > Returns Management > RTV Entry/Update

Enter or select the RTV number of the record that you want to void. The original information is displayed.

Click Void.

RTV entry details

When the RTV record is created, the default account numbers, for distribution types Inventory Offset and Purchase from RTV type accounts will be used if they aren’t empty. The inventory and accounts payable account numbers always will be the default from the item master record and vendor master record, respectively, or if empty, from the posting accounts.

When the RTV record is created and the Account Number in RTV Type Accounts is blank, the default account numbers are based on the following information.

| Account | Location |

|---|---|

| Inventory | Inventory account from Item Master record; if empty, then from Posting Accounts – Sales |

| Inventory Offset | Purchases account from Vendor Master record; if empty, then from Posting Accounts – Sales |

| Purchases | Purchases account from Vendor Master record; if empty, then from Posting Accounts – Sales |

| Accounts Payable | A/P account from Vendor Master record; if empty, then from Posting Accounts – Sales |

If amounts exist in the Cost or Reimbursement fields on the RTV, the following general ledger distribution records will be created. For amounts in the Cost area, the sum of all cost amounts will be the debit entry.

| Account | Location |

|---|---|

| Purchases | Cost Account from RTV Type Accounts; if empty, then the Purchases account from Vendor Master; if empty, then from Posting Accounts |

| Accounts Payable | A/P account from Vendor Master; if empty, then from Posting Accounts – Sales |

For amounts in the Reimbursement area, the sum of all reimbursements amounts will be the credit entry.

| Account | Location |

|---|---|

| Purchases | Reimbursement Account from RTV Type Accounts; if empty, then the Purchases account from Vendor Master; if empty, then from Posting Accounts – Sales |

| Accounts Payable | A/P account from Vendor Master; if empty, then from Posting Accounts – Sales |

Chapter 4: Posting procedures

There are several areas within Returns Management where transactions are posted to update other modules. Some of these areas include RMA receiving, RTV shipping, and inventory transfers. When transactions are posted, they become permanent audit trail information and update the appropriate returns information, create inventory transfers or adjustments, and generate general ledger journal entries.

For example, when you create an RMA, the information is available within only Returns Management. After you’ve posted RMA receiving, inventory reflects an increase adjustment for the item and a debit updates the inventory account in General Ledger for the item being received.

Each of the types of posting routines that can be accomplished within Returns Management is explained below. If you need more general information about posting and the audit trail created by the posting process, see the System User’s Guide (Help > Printable Manuals).

This information is divided into the following topics:

Receive an RMA shipment

Close an RMA

Ship an RTV

Receive an RTV

Close an RTV

Transfer inventory

Inventory receipts

Receive an RMA shipment

You can enter the receipt of a returned item on an existing RMA document at the appropriate return location.

The RMA Receiving window is a multi–purpose window where you can perform the receiving process for your RMAs and print the Traveler Report.

When you receive an RMA, the following transactions are generated.

For RMAs originating from a service call, the inventory transfers are received.

For credit, replacement, or cross–ship RMAs, an inventory adjustment journal is posted.

For repair RMAs, no inventory adjustments are made because of the “customer–owned” setting, but the RMA is marked as received.

When the Return Item Number is changed in RMA Receiving and the RMA did not originate from a Service Call Returned line, the general ledger distributions with no record type (LINITMTYP) are deleted and re–created.

The default account distribution is based on data entered in the RTV Entry/Update window. For more information, see RMA entry details.

The following table explains how the account field is populated:

| Account | Location |

|---|---|

| Inventory | Inventory account from Item Master record; if empty, then from Posting Accounts -Sales |

| Inventory Offset | COGS account from Return Item Master record; if empty, then from Posting Accounts-Sales |

Note

This table is based on the Posting Accounts From option (Item or Customer) selected in the Sales Order Processing Setup window.

(Microsoft Dynamics GP menu > Tools > Setup > Sales > Sales OrderProcessing)

The default account numbers for Sales and Accounts Receivable are based on the following information.

| Account | Location |

|---|---|

| Sales | Sales Returns account from RMA Type Account; If empty, from Sales Account on Return Item Master record; if empty, then from Posting Accounts - Sales |

| Accounts Receivable | Accounts Receivable account from Customer Master record; if empty, then from Posting Accounts – Sales |

Note

This table is based on the Posting Accounts From option (Item or Customer) selected in the Sales Order Processing Setup window.

(Microsoft Dynamics GP menu > Tools > Setup > Sales > Sales Order Processing)

When the Return Item Number is changed in RMA Receiving on an RMA that originated from a Service Call Returned line, a decrease inventory adjustment for the original Item Number and an increase inventory adjustment for the Return Item Number are posted. The default account numbers for these inventory adjustments are based on the following information.

Decrease Adjustment

| Account | Location |

|---|---|

| Inventory | Inventory Account from Source Service Call Returned line Distributions |

| Inventory Offset | COGS Account from the Source Service Call Returned line Distributions |

Increase Adjustment

| Account | Location |

|---|---|

| Inventory | Inventory Account from Return Item master; if empty, then from Posting Accounts – Sales |

| Inventory Offset | COGS Account from Return Item master; if empty, then from Posting Accounts – Sales |

Note

This table is based on the Posting Accounts From option (Item or Customer) selected in the Sales Order Processing Setup window. (Microsoft Dynamics GP menu > Tools > Setup > Sales > Sales Order Processing).

Open the RMA Receiving window. Transactions > Returns Management > RMA Receiving

Select a way to view the RMA documents. To view all open RMA documents, select All.

Select the M (Marked to Post) check box to have the RMA line item show up on the preview report or to post it.

When you select the Mark All option, you will be asked whether you want to select the M (Marked to Post) option, the P (Print the Traveler Report) option, or both.

- If your organization uses multiple bins, click Bins for each RMA line item. You can specify the bins where the received items should be placed when received.

This button is not available for kit items. You can use the Bins button in the RMA – Kit Components window to specify bins for kit components.

If the RMA line item is a kit item, click Kits to view or modify information for the kit components.

If the RMA line item is a serial- or lot-numbered item, click Serial/Lot to enter or verify the serial and lot numbers received for the line item. To automatically receive the previously selected serial numbers for all selected RMA line items, select the Receive All Serial Numbers check box. The Serial/Lot button is not available for kit items. You can use the Serial/Lot button in the RMA – Kit Components window to specify serial or lot numbers for kit components.

Click Misc. Items to add any information regarding accessory equipment, such as power cords or cables to be noted on the return document. These items aren’t adjusted into inventory as part of the receiving process, but simply are recorded as part of the return.

Select the P (Print the Traveler Report) option to have the Traveler Report print with the RMA line item when you post it.

Click Post.

IMAGE – FARM11.jpg

A screenshot of a cell phone Description automatically generated

Close an RMA

When the RMA process is complete, you can create an invoice for any repair or additional charges. Only those RMA documents that have been selected as Ready To Close in the RMA Entry/Update window will appear in the RMA Closing window.

The RMA Closing window is a multi–purpose window where you process the closing of your RMAs. You can use this window to create invoices and print the RMA document information.

If the Repair Price is changed in the RMA closing window, the distribution record with LINITMTYP of Returned are deleted and re–created with default account numbers based on the following information, regardless of source document when the user leaves the Repair Price field.

The default account distribution is based on data entered in the RTV Entry/Update window. For more information, see Set up options and default entries.

The following table explains how the account field is populated.

| Account | Location |

|---|---|

| Sales | Repair Sales account from RMA Type Accounts; if empty, Sales Account from Invoice Item master; if empty, from Posting Accounts – Sales |

| Accounts Receivable | A/R Account from Customer master; if empty, from Posting Accounts – Sales |

Note

This table is based on the Posting Accounts From option (Item or Customer) selected in the Sales Order Processing Setup window (Microsoft Dynamics GP menu > Tools > Setup > Sales > Sales Order Processing).

Open the RMA Closing window. Transactions > Returns Management > RMA Closing

Select a way to view the RMA documents. To view all open RMA documents, select All.

Select the M (Marked to Post) check box to have this RMA show up on the preview report or to close it. Click Mark All to choose all RMAs available for closing.

If the RMA line is a kit item, enter information in the Repair Cost and Repair Price fields. When a kit item is marked for closing, the related kit items also are closed, even though they are not displayed in this window.

Click Preview to print a preview of the items selected for closing. Select the P (Print) check box to include a detailed report of the records posted during the closing process.

Click Post.

IMAGE – FARM12.jpg

A screenshot of a cell phone Description automatically generated

Ship an RTV

The RTV Shipping window is a multi–purpose window where you can perform the shipping process for your RTVs. You also can print a packing slip to send along with the piece of equipment.

You can select and post RTVs that are ready to be shipped to the vendor. The shipping process creates a credit voucher in Payables Management for the cost of the returned item on all RTVs except repair and return types, as well as create a purchase order for any replacement type RTVs. Inventory adjustments are created to decrease the returned item from inventory for a credit, replacement, or cross–ship RTV.

For repair type RTVs, the inventory is transferred to the vendor site ID specified on the RTV. No inventory transactions are created from an RTV line that is marked as customer owned.

When an RTV is shipped, the inventory adjustment posted will update the following general ledger accounts.

The default account distribution is based on data entered in the RTV Entry/Update window. For more information, see Set up options and default entries.

The following table explains how the account field is populated:

| Accounts | Location |

|---|---|

| Inventory | from Item master, if empty, then from Posting Accounts – Sales |

| Inventory Offset | from Item master, if empty, then from Posting Accounts – Sales |

During the shipping process a credit voucher also is created in accounts payable and when posted, updates the following accounts.

| Accounts | Location |

|---|---|

| Accounts Payable | from Vendor master, if empty, then from Posting Accounts – Sales |

| Purchases | from Vendor master, if empty, then from Posting Accounts – Sales |

- Open the RTV Shipping window.

Transactions > Returns Management > RTV Shipping

Select a way to view the RTV documents. To view all open RTV documents, select All.

Select the Consolidate PO check box to combine items going from different RTVs to the same vendor onto one purchase order document. In order for an item to be consolidated on an existing purchase order, the PO must meet the following criteria.

The PO Status must be “New”.

The PO must have the same vendor ID as the current RTV being shipped.

Select individual RTV lines and enter or modify the shipping method and tracking number information. This is the outbound shipping information.

Select M (Marked to Ship) to display this RTV on the preview report or to post it.

Select P (Print**)** to print the packing slip with the RTV when you post it.

When you click Mark All, you will be asked whether you want to select the M (Mark to Post) option, the P (Print the Packing Slip) option, or both.

Click Post.

Receive an RTV

You can access an existing RTV document and record that the item was received from the vendor. The RTV Receiving window is used to complete the transfer process for only a repair and return RTV or for cross–ship and replacement RTVs if you aren’t registered to use Purchase Order Processing.

The RTV Receiving window is a multi–purpose window where you can perform the receiving process for your RTVs. You can use this window to select and receive your RTVs that are ready to be received.

When the inbound Item Number is changed in the RTV Receiving window on a repair and return RTV, a decrease inventory adjustment for the outbound Item Number and an increase adjustment for the inbound Item Number are posted. The default account numbers for these inventory adjustments are based on the following tables.

The default account distribution is based on data entered in the RTV Entry/Update window. For more information, see Set up options and default entries.

Decrease Adjustment

| Account | Location |

|---|---|