Note

Access to this page requires authorization. You can try signing in or changing directories.

Access to this page requires authorization. You can try changing directories.

Important

This content is archived and is not being updated. For the latest documentation, go to What's new or changed in Dynamics 365 Supply Chain Management. For the latest release plans, go to Dynamics 365 and Microsoft Power Platform release plans.

| Enabled for | Public preview | General availability |

|---|---|---|

| Users by admins, makers, or analysts |  Oct 15, 2021

Oct 15, 2021 |

Dec 10, 2021

Dec 10, 2021 |

Business value

Manufacturing execution systems integration offers manufacturers a fast path to realizing their Industry 4.0 ambitions by making it faster and easier to integrate Dynamics 365 Supply Chain Management with common manufacturing execution systems. The solution reduces overall implementation and operating costs. It helps manufacturers to establish end-to-end visibility and control over the production floor.

Feature details

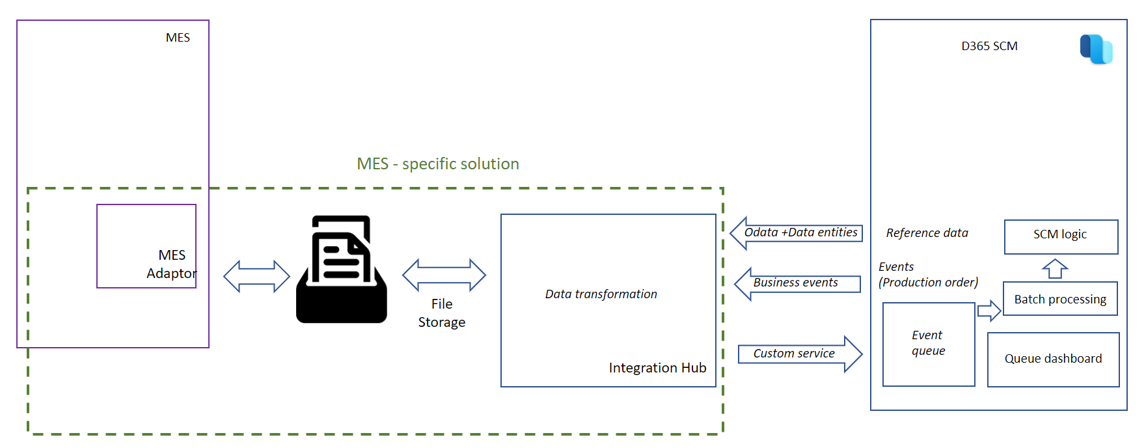

Some manufacturing organizations that use Supply Chain Management, especially those with advanced manufacturing requirements, use a third-party manufacturing execution system (MES) to control their manufacturing activities for machines, equipment, and personnel instead of what is natively available in Dynamics 365. Organizations might choose a third-party MES solution (for example, because it is tailored for their own vertical industry).

In the integrated solution, data exchange is fully automated and near real time, which keeps data current in both systems and eliminates the need for manual data entry. For example, when material consumption is registered in the MES system, the integration ensures that the same consumption is also registered in Dynamics 365, so up-to-date inventory records are available to other important processes such as planning, sales, and so on.

The solution makes it faster, easier, and cheaper for Supply Chain Management users to integrate with third-party MES systems. It offers:

- Business events and interfaces that support key manufacturing execution processes

- A centralized dashboard where the event processing history can be tracked and failing processes can be troubleshooted and resolved

You can enable any or all processes outlined in the following subsections for integration.

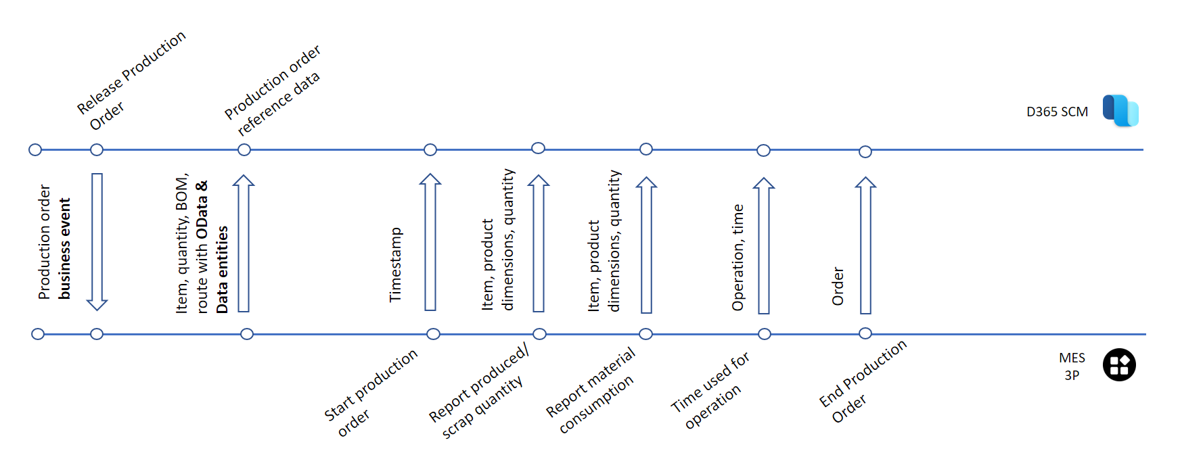

Release production orders and production order status change

This process provides the MES system with a business event that the MES can monitor for information about which production orders to produce. Reference data related to the production order is expected to be provided with OData or data entities.

Start production order

This process provides Supply Chain Management with information about production orders being started using the MES system. It ensures that both systems have an up-to-date view of all manufacturing activities.

Report produced or scrapped quantity

This process provides Supply Chain Management with information about the good and error quantities reported on a production job using the MES system, which provides shop floor supervisors with an up-to-date view of production plan progress.

Report material consumption

This process provides Supply Chain Management with information from the MES system about quantities of materials consumed. This makes up-to-date inventory records available to other important processes such as planning, sales, and so on.

Report time consumed for the operation

This process provides Supply Chain Management with information on the time used for a specific operation.

End production order

This process tells the MES system that a production order has been updated to its final status of Ended in Supply Chain Management, which indicates that no more quantities will be produced for the production order.

See also

Learn about manufacturing execution systems integration (video)

Integrate with third-party manufacturing execution systems (docs)