Note

Access to this page requires authorization. You can try signing in or changing directories.

Access to this page requires authorization. You can try changing directories.

Important

This content is archived and is not being updated. For the latest documentation, go to What's new or changed in Dynamics 365 Supply Chain Management. For the latest release plans, go to Dynamics 365 and Microsoft Power Platform release plans.

Important

Some of the functionality described in this release plan has not been released. Delivery timelines may change and projected functionality may not be released (see Microsoft policy). Learn more: What's new and planned

| Enabled for | Public preview | General availability |

|---|---|---|

| Users by admins, makers, or analysts |  Jul 29, 2022

Jul 29, 2022 |

To be announced |

Business value

A growing number of companies want to control their supply chain based on Demand Driven Material Requirements Planning (DDMRP) principles. This typically yields inventory reductions of 30-45 percent while improving customer service. With this release, the Planning Optimization Add-in for Dynamics 365 Supply Chain Management fully supports the DDMRP principles. With native DDMRP support in Planning Optimization, customers can benefit from DDMRP supply chain optimization without the need for external solutions.

Feature details

DDMRP is a formal multi-echelon planning and execution method for protecting and promoting the flow of relevant information through the establishment and management of strategically placed decoupling point stock buffers. DDMRP combines aspects of Material Requirements Planning (MRP) and Distribution Requirements Planning (DRP) with the pull and visibility emphases found in Lean and the Theory of Constraints, and the variability reduction emphasis of Six Sigma. These elements are successfully blended through key points of innovation in the DDMRP method. DDMRP is the supply-order generation and management engine of a Demand Driven Operating Model (DDOM). DDMRP can best be summarized as "position, protect, and pull."

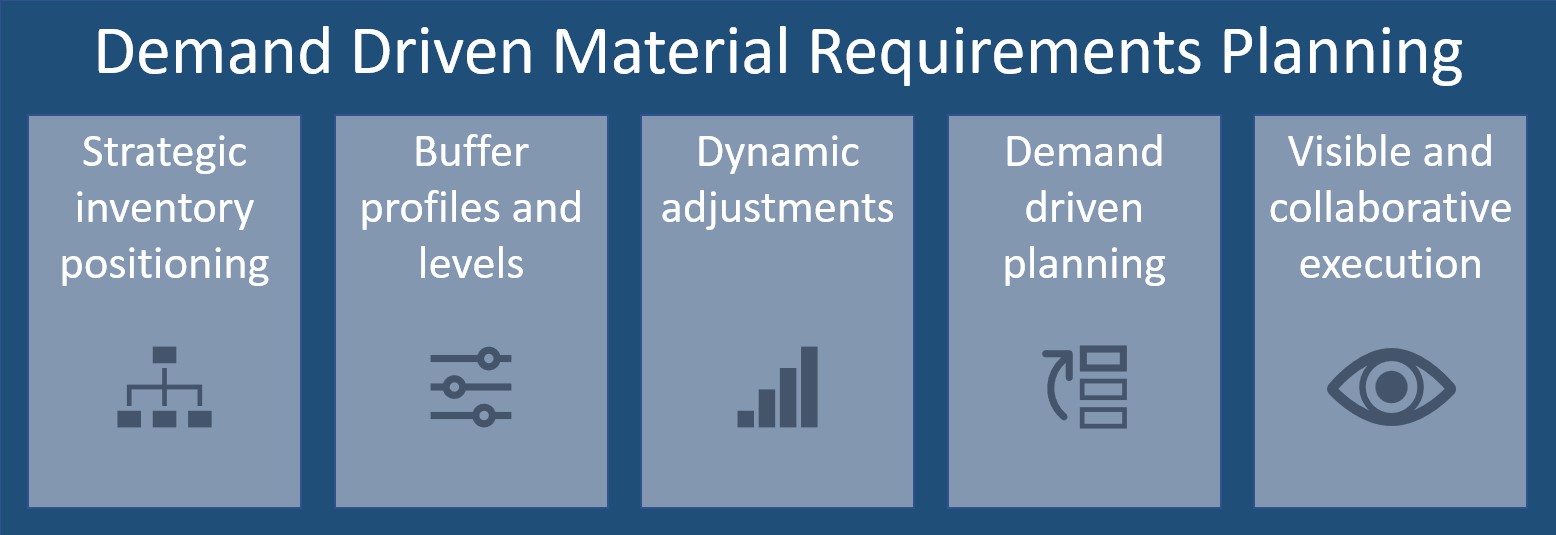

The five sequential components of DDMRP

DDMRP has five sequential components:

- Strategic inventory positioning: Determines where the decoupling points are placed.

- Buffer profiles and levels: Determines the amount of protection at those decoupling points.

- Dynamic adjustments: Defines how the level of protection flexes up or down based on operating parameters, market changes, or planned or known future events.

- Demand-driven planning: The process by which supply orders (purchase orders, manufacturing orders, and stock transfer orders) are generated.

- Visible and collaborative execution: The process by which a DDMRP system manages open supply orders.

The first three components essentially define the initial and evolving configuration of a DDMRP model. The final two elements define the day-to-day operation of the method. DDMRP is typically the start of an organization's transformation to a demand-driven adaptive enterprise.

Main components of the DDMRP offering for Planning Optimization

The DDMRP offering for Planning Optimization includes the following main components:

- Inventory positioning: Enable companies to calculate and identify the decoupled lead time (DLT) for purchased, distributed, and manufactured items.

- Buffer profiles: Group items into independently managed families with variable settings for zone impact. Calculate DDMRP buffers and zone values using a combination of buffer profile attributes and the individual part traits of usage, lead time, and order minimum.

- Dynamic buffer adjustments: Dynamically altering buffers for planned or anticipated events. Maintained as minimum, re-order point, and maximum.

- Demand-driven planning:

- Perform the DDMRP net flow equation, including qualifying sales order demand (due today, past due, and qualified spikes).

- Display net flow status (color, percentage, and quantity) for easy prioritization and supply order generation.

- All elements of the net flow equation are visible on the planner workbench.

- Highly visible and collaborative execution: Display alerts based on buffer status for on-hand position.

Planning Optimization benefits

With Planning Optimization, companies can benefit from:

- Significantly improved performance and scalability with in-memory processing.

- Minimized system impact on other processes made possible by running master planning as a separate service.

- Near real-time insights into requirement changes, achieved by running master planning several times daily during office hours.

Learn more about Planning Optimization

For more information about the Planning Optimization migration process and answers to frequently asked questions, see Migration to Planning Optimization for master planning.

See also

Demand Driven Material Requirements Planning (DDMRP) overview (docs)