Configure warehouses

A warehouse is a place that can store items. All items that the system accounts for must be in a warehouse. Because many parameters and policies are set up for each warehouse, you can control and differentiate the warehouse operations by defining several warehouses.

Usually, a warehouse is a geographic location or it serves a certain function, such as a spare parts warehouse or a finished goods warehouse. When you have several warehouses, you can split up the total available inventory. You can attach all item transactions to a warehouse that follows the transactions throughout the system.

When you indicate a warehouse for a transaction, specify the site where you can place or pick an item geographically. This approach means that you use separate warehouses for distinct geographic locations.

In some cases, you can have virtual warehouses, meaning that the warehouse might not be a separate physical building but might be a logical separation or part of a building. You can use this strategy to meet complex business requirements.

To create a new warehouse, go to Inventory management > Setup > Inventory breakdown > Warehouses.

You shouldn't use a warehouse as a financial inventory dimension. Instead, you should create separate sites.

Warehouse types

When you create a warehouse, specify a warehouse type as follows:

Default - A main warehouse.

Quarantine - Attach warehouses of the Quarantine type to regular warehouses of the Default type. When you purchase items that are quarantine-controlled to a warehouse, the system automatically puts them in the warehouse of the Quarantine type that's attached to the receiving warehouse. When you end the quarantine, the system transfers the items to the specified receipt warehouse.

Transit - Use for transfer orders and the delivery date control function. Transit warehouses are the system-technical intermediary warehouses between the From and To warehouses or warehouse and delivery location with the delivery date control functionality.

You could organize a warehouse into locations to keep stocked items in their proper locations. Usually, in a simple warehouse, a warehouse location has a format of aisle-rack-shelf-bin.

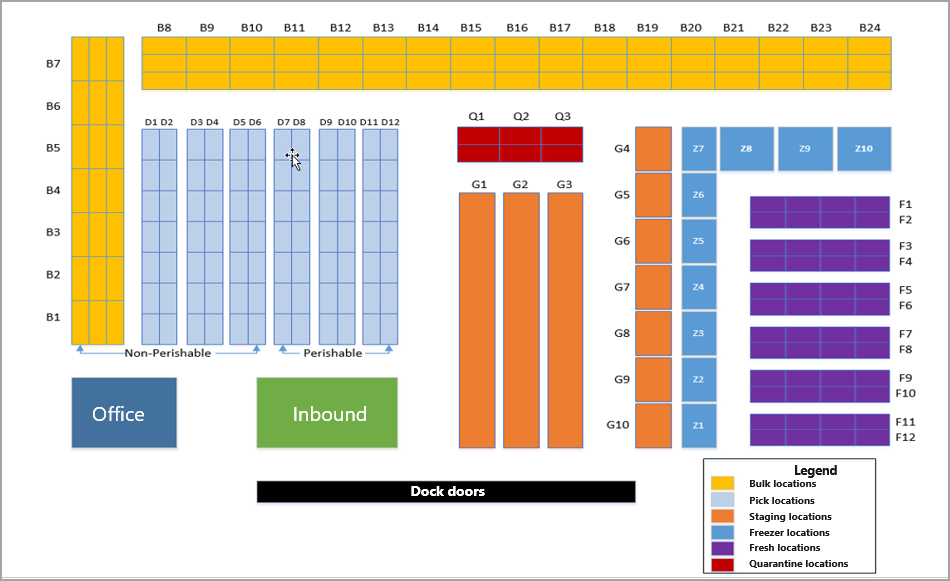

The following figure illustrates an example of a grocery store warehouse layout.

You can specify transport times for the selected warehouse by selecting the Transport button. The system uses transport times in the delivery date calculation when you use the delivery date control with transfer orders.

If you don't specify a warehouse on the product, you can specify the warehouse from which to sell or purchase the products on the sales and purchase order header and on the individual lines.

The warehouse that you specify in the header applies to all lines, unless you specify otherwise individually on the product or manually on an order line.

Inventory aisles

A warehouse is divided into inventory aisles, which you can use to group locations. An aisle has an aisle ID and an aisle number, which can be the same. The aisle ID, typically the first part of the location name, is an alphanumeric identifier for an aisle. The letters help identify a warehouse or area in the warehouse.

The aisle number is a strictly numeric identification of the aisle in the warehouse. The system uses the aisle number when it generates sorting codes. You can assign unique IDs to the inventory aisle by using the Warehouse and Aisle fields.

By default, the system sorts inventory aisles in ascending order. By selecting the Descending field, you can reverse the picking route for the relevant aisle. This setting changes the order from the highest value to the lowest value.

Location

Location refers to the place that you store and draw items from. Location is the most specific indication of where the items are stored in the warehouse. For each location, you can also specify the place where you insert the item. By default, they are the same. Usually, you would insert and draw Items from the same side of a location, but not always. For example, you can insert items that are stored in live storage racks, or flow racks, from one aisle and then draw them from another.

A location name gives the main input. You can determine the location name from its coordinates: warehouse, aisle, rack, shelf, and bin. On the Inventory locations page, you can enter this name or ID manually or the system generates it from the location coordinates, for example: 1-2-3-4 for aisle 1, rack 2, shelf 3, bin 4.

A location has the following characteristics:

Size (height, width, depth, and thereby volume)

Warehouse (aisle, rack, shelf, and bin position)

Location type (bulk location, picking location, inbound dock, outbound dock, production input location, inspection location, or kanban supermarket)

Check text, which you can use in online systems to verify that the operator selects the correct location for a specific item. You can create this check text manually or use the default.

Examples of location types include:

Bulk location - The area in the warehouse where received items are stored until the warehouse worker transports the items to the picking locations. You can use bulk locations to replenish picking locations as their stock reduces. Additionally, you can use bulk locations for picking.

Picking location - Where items are stored until workers pick them for shipment. Keep items in the picking location to ensure easy access for picking. You can use the picking location to pick small quantities of an item. An item can have only one picking location in each warehouse.

Inbound dock - Location in the warehouse where you can receive items and possibly check them (this is the default if you don't specify it elsewhere).

Outbound dock - Location in the warehouse where shipment occurs (this is the default if you don't specify it elsewhere).

Production output location - Location where the finished items from the shop floor arrive.

Inspection location - Location where the inspections occur.

Kanban supermarket - Location where you can control and process the inventory for work-in-progress (WIP) products in a lean manufacturing environment.

The use of a location is optional. If you use locations, the system can determine pick routes, counting operations, and other decisions based on the locations where the items are stored.

Location placement

You can categorize location placement in two ways:

Input areas - Locations in the warehouse that are designated for item placement in the warehouse on receipt. The system groups items based on similar characteristics or the order in which you place them in their locations. You can specify the input area for a location on the General tab of the Inventory locations page. For example, items that require cold storage would be in one input area, whereas items that are safe to store in the general warehouse storage area would be in another.

Picking areas - Assign picking areas throughout a warehouse to group items that workers should pick simultaneously or items that one person should pick. You can specify the picking area for a location on the General tab of the Inventory locations page. For example, items that require a forklift for picking and transport would be in one picking area, whereas items that a warehouse worker can pick individually from a floor level with a hand truck would be in another.

The following video demonstrates how to create locations for a warehouse.

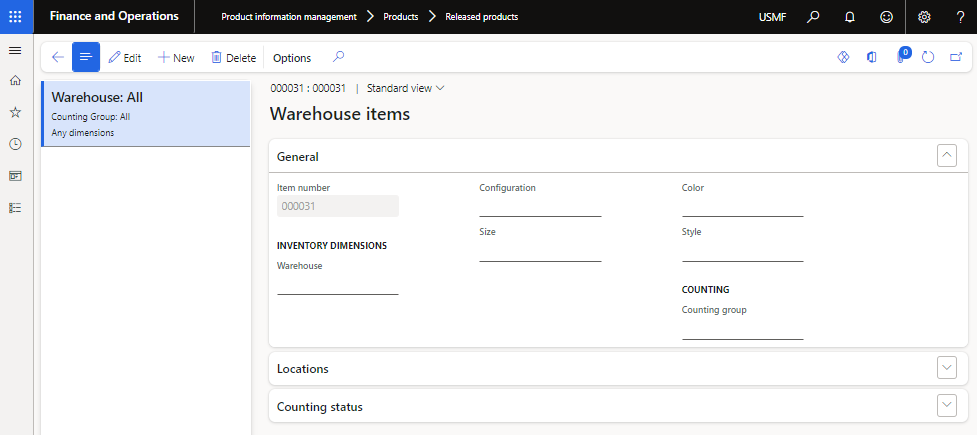

Warehouse items

After you set up the warehouse with aisles, locations, and store zones, you can assign products to the warehouse. You can define multiple warehouse items for each product. By default, the system creates a blank warehouse item when you save the product. You can't modify product dimensions on this blank warehouse item. However, you can update other settings.

Product information management > Products > Released products > Manage inventory tab, Warehouse group > Warehouse items

For each warehouse item that you create, you can also select different options for the following fields:

Counting group - Determines the frequency of cycle counting.

Default receipt location - Defines the location that the system uses by default on item receipt.

Default issue location - Defines the location that the system uses by default on item delivery.

Picking location - Defines the default location that workers pick the item from.

The Default receipt location, Default issue location, and Picking location fields are available only when the storage dimension group that's assigned to the item has the Location dimension activated. Also, these fields aren't available for the default blank warehouse item that the system creates.