Determine value and process selection

Most organizations have multiple, active business processes, but not all of those processes are good candidates for improvement through process mining. To ensure that you're using process mining on the highest impact processes, you need to determine the value of possible improvements. Then, you should use that assessment as part of your selection process and prioritization of your potential processes.

When to use process mining

Considerations for effective process mining include:

Process analysis - Process mining helps businesses understand how their processes work in practice, how they deviate from the intended design, and where bottlenecks occur.

Process improvement - Process mining helps organizations identify areas where they need process improvements, such as reducing lead times, decreasing waiting times, or optimizing resource allocation.

Compliance and auditing - Process mining helps ensure compliance with regulations and internal policies by detecting noncompliant behavior and deviations from standard procedures.

Performance monitoring - Process mining helps organizations monitor process performance in real time, and it helps them identify potential problems before they occur and then proactively address them.

When process mining might not be the best option

Certain considerations indicate that process mining might not be as effective or appropriate, including:

Lack of data - Process mining relies on event logs from information systems, so if limited or no data exists, it might not be possible to perform process mining.

Real-time processes - If the process that you're analyzing is complex or dynamic, process mining might not be able to capture all relevant information, or it might be difficult to interpret the results.

Unstructured or repetitive - If processes are unstructured or are repetitive in nature, process mining might not generate valuable insights or provide clear results.

Lack of process understanding - Process mining is most effective when you have a clear understanding of the process that you're analyzing. Processes that aren't well understood can produce results that are difficult to interpret.

Limited resources - Process mining can be time-consuming and resource-intensive, so if technical and business resources don't align, it might not be feasible to conduct a process mining analysis.

Evaluate potential processes for process mining

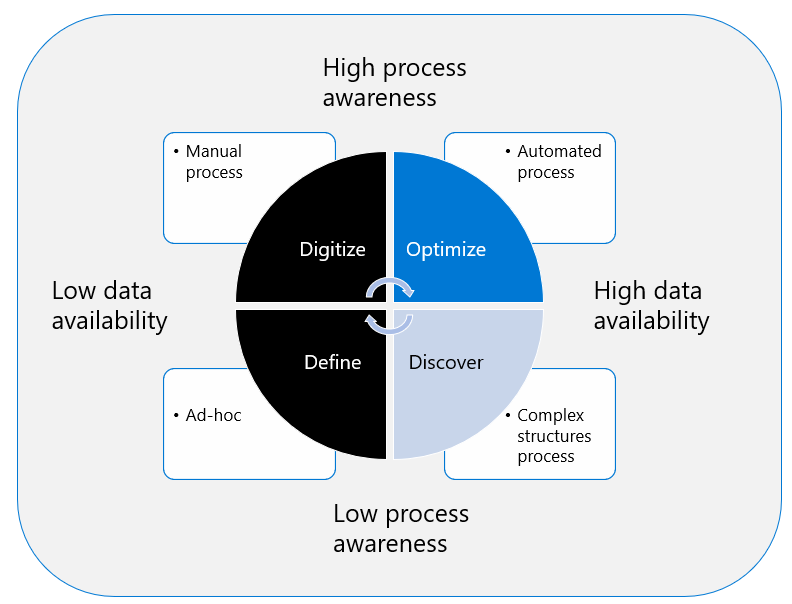

During the planning stage, you should rank and categorize your projects to ensure that you're working on appropriate projects that produce the most benefit. The following diagram illustrates, at a high level, how to use data availability and process awareness as broad indicators of whether a process is a good candidate to analyze with process mining.

In this context, data availability means that the system captures telemetry on the completion of steps in the process, which can help facilitate process mining. When a process already has good telemetry available, you can bring that telemetry into process mining so that it can perform analysis of the overall process. A process with low data availability would require you to significantly invest in modifying the steps in the process. Consequently, you would need to collect appropriate step completion telemetry before you can perform process mining on the process.

Impromptu processes lack structure and consistency that you can optimize. You would complete an impromptu process to react to events as they occur. Frequently, these processes have limited telemetry available on the completed steps. Moreover, it's common for organizations not to consider these processes as high awareness or high impact. In general, these types of processes aren't good candidates for process mining analysis. Instead, they could benefit from a more basic process design effort to define a more structured process. Manual processes that have high awareness and high impact on the organization would be good candidates; however, they typically lack the telemetry to make it possible for you to use process mining. Before you use process mining on these types of processes, they must first undergo digital transformation. As you digitize the process, you can add proper telemetry from the start to allow process mining to perform further continuous improvements in the future.

Processes that have high data availability are ideal candidates for process mining. For processes that are already heavily automated, you can use process mining to further optimize. For complex processes, you can often use process mining to identify opportunities to further automate and simplify.

Evaluate the value of potential improvements

As part of your effort to prioritize processes, estimating the potential value of improvements can help ensure that you analyze the correct processes. Not all process improvements are cost or revenue improvements; some result in more intangible benefits. Evaluating potential processes by using a non-monetary ranking, such as high, medium, or low, can help ensure that all high-value processes receive proper prioritization.

By following a structured approach to prioritize and select processes, you can ensure that your process mining efforts are dealing with the processes that can provide the highest impact to your organization.