Use the production journal

The production journal combines the functions of the consumption journal and output journals into one. This journal provides a single interface to register consumption and output from a production order.

The production journal enables you to:

Record output and consumption for a production order.

Relate component consumption to operations.

Relate actual operation data with the standard estimates on the production order routing line and production order BOM.

Post and print an overview of registered operation data for the production journal.

The production journal has many similar functions as the consumption and output journals. It handles dimensions, item tracking, and bin contents similarly as the consumption and output journals. However, the production journal differs from the consumption and output journals in that it:

Is called directly from a released production order.

Is predefined with the relevant component data from the production order BOM and the routing data from the production order routing.

Displays operations and components together in a logical structure that provides an overview of the production process.

Displays quantities and times that are already posted for the order at the bottom of the journal as actual entries.

Enables you to define the types of component and routing lines to view based on a flushing method filter at the top of the journal.

Allows you to set up the way that output quantities are predefined in the journal. For example, you can specify that the last operation must have zero as its output quantity.

Doesn't allow you to edit fields where data entry is irrelevant.

Displays a request message that lets you remain in the journal if you try to exit the journal without posting the changes that you entered.

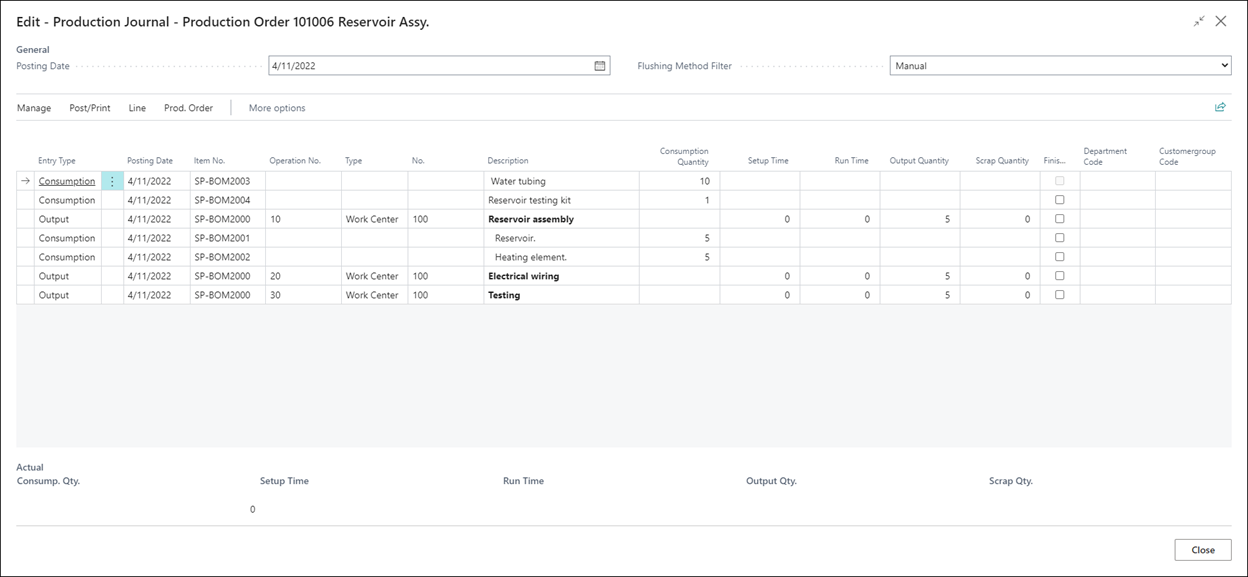

The following steps show how to use the production journal for a released production order for five units of item SP-BOM2000 (Reservoir Assembly). The first step is creating the released production order.

Select the Search for page icon in the upper-right corner of the page, enter released production orders, and then select the related link.

Select New.

In the Source Type field, select Item.

In the Source No. field, enter SP-BOM2000.

In the Quantity field, enter 5.

Select Refresh Production Order and then select OK.

To open the production journal, select Line > Production Journal.

When no routing link codes are assigned, the components are shown at the top, with the routing operations beneath. If routing link codes on the production BOM and routing exist, the components will be listed beneath the operation to which they're linked. In the preceding image, the first two components have no routing link codes and they're displayed at the top. Components SP-BOM2001 and SP-BOM2002 are linked to operation 10, which is why they're displayed beneath the Reservoir assembly operation.

You can set the posting date in the Posting Date field in the header. This field provides a quick method to align posting dates on all lines. It initially uses the work date; however, you can change it as required.

You can set the Flushing Method Filter field to view consumption and output that are recorded by specific flushing methods. You can also specify All Methods to view all consumption and output lines, regardless of their flushing method.

To post consumption and output, you'll enter the following fields similar to how you entered them in the consumption journal and output journal:

Consumption - Consumption quantity

Output

Setup time

Run time

Output quantity

To post the production journal, select Post/Print > Post > Yes.