Working with Overlap in Microsoft Dynamics AX

Conducting Dynamics AX Manufacturing training for a class in Malaysia, it became clear that the current documentation on Overlap in Dynamics AX was not telling the full story.

Therefore, I decided to write this blog.

So, what is Transfer batch and Overlap quantity?

In Dynamics AX ‘Transfer batch’ is the field used to control an overlapped schedule. Apics define ‘Overlapped schedule’ as “A manufacturing schedule that overlaps successive operations. Overlapping occurs when the completed portion of an order at one work center is processed at one or more succeeding work centers before the pieces left behind are finished at the preceding work centers.”

Overlapped schedule is also known as lap phasing, operation overlapping, telescoping or send ahead.

‘Overlap quantity’ is a calculated field on the production order – ensuring that we avoid gaps in the schedule, when the successor operation to the operation with a Transfer batch value, has a shorter process time.

The ‘Overlap quantity’ determines the first transfer batch size for the operation; the following transfers to the next operation will use the ‘Transfer batch’ value.

Overlap quantity example

Say you have a production order for 10 pcs and it has two operations 10 and 20, each operation taking 2 minutes per pcs:

Without overlap:

Normally operation 20 will start when the entire quantity (10 pcs) has been processed on operation 10

With overlap:

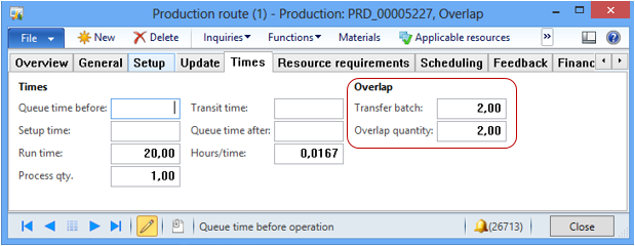

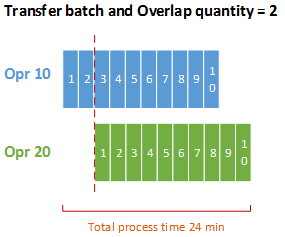

When you have specified something in ‘Transfer batch’ field, let us say 2 pcs, it means the next operation (in our case 20) can already start when only 2 pcs has been processed on the operation 10. The value from ‘Transfer batch’ is by default copied to the ‘Overlap quantity’, on the production order.

Why does the Overlap quantity sometimes change when I estimate a production order?

The ‘Overlap quantity’ parameter on the production order route is calculated by the system. This is done during the estimation (or scheduling) of the production order, to prevent gaps in situations where a later operation have a shorter process time than the current operation. The fact that the successor would be waiting for the delivery from the predecessor would be causing a gap.

So, the calculation of an optimal ‘Overlap quantity’ is done based on the ‘Transfer batch’ and the operation process durations on the route.

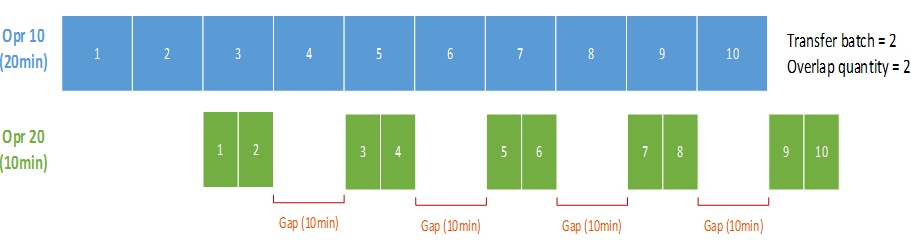

Overlap example with gaps (two operations):

Say you have a production order for 10 pcs and it has two operations 10 and 20, this time the first operation takes more time than the second does:

Opr 10: 20 min per pcs

Opr 20: 10 min per pcs

Again, we have a Production order for 10 pcs and Transfer batch quantity set to 2 pcs

Without any change during Estimation the jobs on the route would have a gapped schedule and look like this:

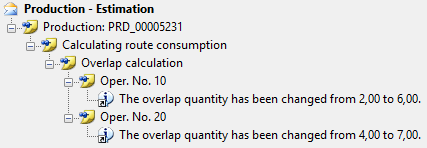

However, as the first operation in total will take 200 min to complete and the second will take 100 min you will get the following information when estimating:

With the change from 2 to 6 we ensure that there are no gaps between the jobs in the second operation.

Overlap example with gaps (three operations):

Now let us spice it up a bit and add another operation – Opr. 30 with a run time of 5 min per pcs. We will also set a ‘Transfer batch’ = 4 on operation 20

In this case, you get the following information during estimation:

Now the schedule will look like this:

Therefore, by updating the ‘Overlap quantity’ on the production order during the Estimation Dynamics AX ensures that production on the following operation can happen without any gaps – avoiding a gapped schedule.

Christian Rytt, Senior Program Manager at Microsoft Development Center Copenhagen

Comments

- Anonymous

May 28, 2013

Thank you for this Christian,It is the most "user friendly" explanation of overlap operations (simultaneous operations, or whatever we want to call these types of route networks) that I have ever seen. - Anonymous

July 31, 2013

The comment has been removed - Anonymous

August 04, 2013

The comment has been removed - Anonymous

August 12, 2013

Hi Christian,Thanks for sharing this explanation. Could you provide us the calculation general formula or equation, to calculate overlapped quantity? - Anonymous

August 12, 2013

Hi Zubair, good to hear from you again :-)The actual calculation is a bit tricky, as it is looking at the actual timing - so I can not point you to a formula in the code. However let's calculate it based on the example above with Opr 10 and 20.There are two basic rules1) Opr 20 can not start before the first transfer batch is completed from Opr 102) The last batch on Opr 20 can not start until the last batch from Opr 10 is completedBased on the second rule we calculate the end time for Opr 20:Opr 20 End time: Opr 10 ends after 200min + 210 min to complete 2 pcs on opr 20 = 220minThen the start time for Opr 20(without gaps):Opr 20 Start time: Opr 20 starts after 220min – (1010min), so 220 -100 = 120 minNow we count the quantity on Opr 10 that can be completed at the start time for Opr 20 (round up if needed) and this will equal our overlap time:Opr 10 takes 20 mins per pcs. so 120min/20 min = Overlap of 6So, the Overlap quantity equals the number of "parts" that can be processed in Opr 10, before Opr 20 starts. - Anonymous

February 10, 2014

Thank you Christian, Very good explanation of overlap calc in Ax - Anonymous

February 11, 2014

Overlap calculation algorithm provided by Microsoftmsdn.microsoft.com/.../prodrouteoverlapcalc.calcoverlap.aspx - Anonymous

March 26, 2014

i have tried based on your explanation, when i used overlap the result that i got was schedulling without overlap. is there any setting that is needed for it ? - Anonymous

April 02, 2014

Thanks very much! 妈妈再也不担心我不懂Overlap了。 - Anonymous

May 01, 2014

The comment has been removed - Anonymous

May 04, 2014

Hi Linda, I'm not familiar with the "overlap" details of Planet Together so I'm having a hard time guiding you on this one. I suggest you contact the folks who delivered Planet Together. - Anonymous

May 04, 2014

Thank you for your response. How do we shut this function off and, if we do shut it off, how does it affect MRP? - Anonymous

June 19, 2014

Hi ChristianDoes scheduling direction matter?? (forward from/backward from...) - Anonymous

July 13, 2014

Great Documentation. I have a situation where it is desirable to have a gapped schedule and would therefore like to know if it is possible to turn off the automated calculation of the overlap quantity for specific operations in a route.The real world Scenario here is:2-3 work Centers (work group 1) serve 1 work Center (machine 4) with product (which can be different items) but all go through the same process on machine 4.The items can run through the process in any order and have varying times on machine 4.The gaps are filled by incoming product from other machines from work group 1. Machine 4 is therefore wotrking on multiple orders and through doing this has very few gaps in reality. The machines run 24/7 in this way.The elimination of gaps actually increases process time by approximately 30% in the above Scenario and is therefore not desirable. I considered creating multiple work centers for machine 4 with reduce capacity so that operations from the work group 1 can be run in parallel but this enables Jobs to close at the same time which is also an incorrect Situation and causes Problems later in the production process. - Anonymous

July 28, 2014

Hi LindaLeaving the Overlap quantity and Transfer quantity blank (zero) will "turn off" this functionality, as in the illustration 'Without overlap'. - Anonymous

July 28, 2014

Hi Tom - No, Overlap works regardless of the scheduling direction (both forward and backward) - Anonymous

July 28, 2014

Hi Andy P - I do see the limitation with the given scenario. We are not planning to change this in the near future. However, one local solution could be to add an option during job scheduling to leave the overlap quantity as is. - Anonymous

November 16, 2015

Thanks this is exactly what I need. Christian can you do more of these for other topics that are in urgent need for a solid explanation with examples? This is a winner.

- Anonymous

February 20, 2017

A common problem if you can’t get overlap to work is that overlap isn’t enabled on the route group. Go to the route group (from the route on the general tab) and check that the overlap options (on the setup tab) are check marked.