Benefits of Supply Chain Management

Supply Chain Management enables organizations to run smarter with connected operations and to perform the following tasks:

Create an ideal manufacturing mix from discrete, lean, and process in a single, unified solution to support processes across the supply chain.

Optimize manufacturing parameters for each product family, including make to stock, make to order, pull to order, configure to order, and engineer to order.

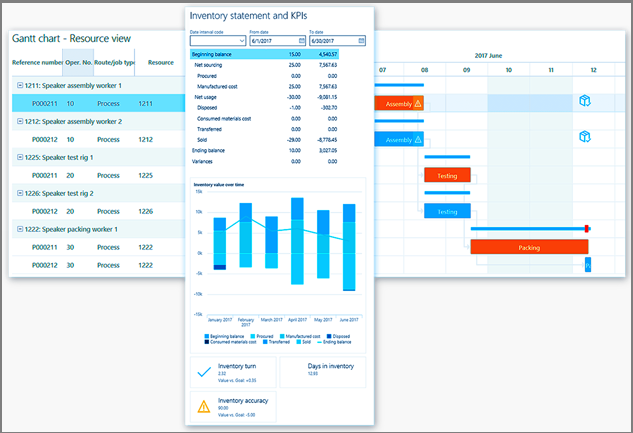

Streamline scheduling with real-time visibility into resources by using a unified resource model and scheduling engine by using the Financial management module in Supply Chain Management.

Optimize the flow of manufacturing material and finished goods with advanced warehouse and logistics management.

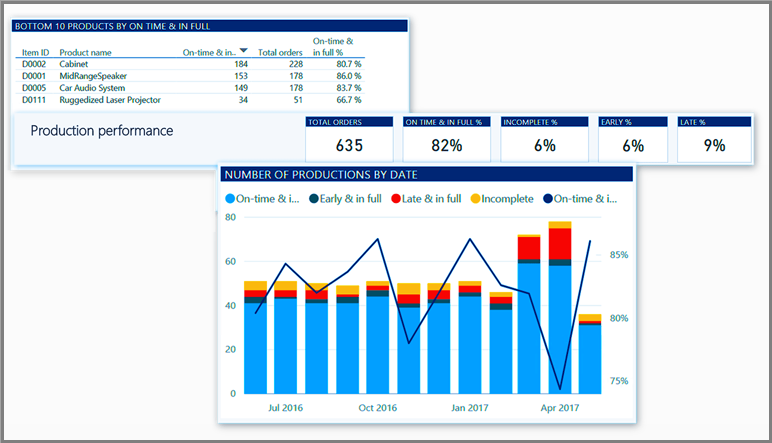

Improve product quality by identifying and resolving issues through real-time insights and predictive intelligence.

Automate and streamline your supply chain

Supply Chain Management helps organizations optimize fulfillment and reduce costs by synchronizing logistics across sites, warehouses, and transportation modes. Additionally, it enables organizations to provide faster response to customer demand by automating a seamless coordination of an order-to-cash processes.

Throughout the operations, Supply Chain Management provides visibility and control across all sites and warehouses for proactive response to issues by using financial analysis capabilities.

By unifying processes from sales to fulfillment, Supply Chain Management seamlessly connects sales and purchasing with logistics, production, and warehouse management for a 360-degree view of an organization’s supply chain. It reduces procurement costs and gains greater control by automating procure-to-pay processes.