The Planned cross docking feature allows you to move inbound inventory for an existing order directly to an outbound dock or staging area. If inventory is not needed for orders, it will be directed to the correct storage location through the regular put-away process. This process minimizes inventory touches, time, and space in the warehouse.

The Cross docking template option is automatically enabled. The following screenshot shows how the template is used at Warehouse management > Setup > Work > Cross docking templates.

The Sequence number indicates the order in which the system will select data from the template. If the data doesn’t meet the criteria specified, the system will move on to the next sequence, and so forth, until the criteria is met (if at all).

The Demand release policy that you would select will be either Before supply receipt or At supply receipt. In other words, the selection depends on whether it will be planned before it is received or if it will be planned only at the time it is received.

The Planning FastTab contains several options:

Demand requirements – Select Marked if the demand is required to be linked to the supply before the release, or select Order reservation if the demand is required against the supply prior to release.

Work creation – Determines how to find the put locations, which are based on location directives or inherited from the locations on the shipment.

Work template – Select this option if you need to set up any cross-docking work templates.

Revalidate on supply receipt – This option indicates whether the supply should be revalidated during receipt or not. If the option is set to Yes, the maximum window and expiration days range will be selected for those time frames.

Validate time window – Indicates if the maximum time window should be evaluated when you are selecting a supply source.

Maximum time window – The maximum time period allowed between the supply arrival and demand departure.

Maximum time window unit – Indicates a maximum time window of days or hours.

Minimum time window – The minimum time period allowed between the supply arrival and demand departure.

Minimum time window unit – Indicates a minimum time window of days or hours.

Expiration days range – The maximum days between the expiration date of the first expiring batch and the batch that is being received.

In the Supply sources area, you can perform the following actions:

Select between Purchase order, Production order, and Transfer order receipt.

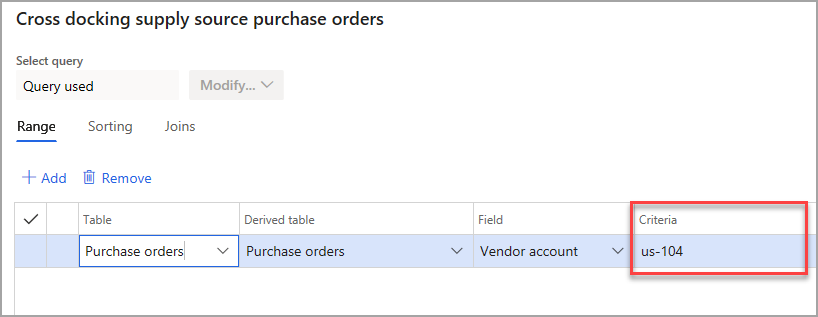

Use the Edit query option to select a specific vendor on a purchase order or another field in the selected supply source (for example).

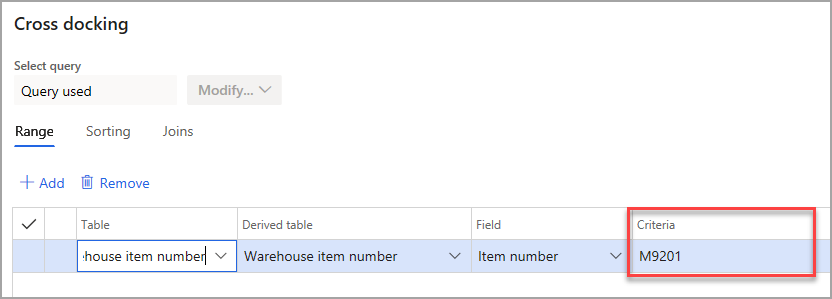

At the top of the page is another Edit query option. However, the only field that it is intended to select is Item number, which will indicate the item(s) that will be cross docked.

Auto-release shipment for cross docking

The Auto-release shipment for cross-docking feature lets you automatically release an order to the warehouse when the production order that supplies the product is reported as finished. The quantity that is needed for the sales order or transfer order is moved directly from the production output location to the outbound location.

As opposed to the earlier discussion of cross docking, this feature only supports production orders as supply and only sales orders and transfer orders as demand.

Cross docking can be started even if the demand order (sales or transfer) wasn't released to the warehouse before the production order was reported as finished.

Example - Cross docking flow for auto-release shipment

The following diagram shows an example of a cross-docking flow for an auto-release shipment.