Inventory on-hand report storage

The on-hand inventory report beneficial in cases where the output contains many inventory lines and is automatically enabled.

For example, requesting the on-hand inventory by item, site, and warehouse in a scenario for 50,000 items and 300 stores would yield a long report, making the data difficult to review. The ability to sort and filter the results in the application or export the results to an external system makes the on-hand inventory report faster and easier to navigate.

Define report parameters

When the report is generated, you'll be asked to specify a unique name for the report, and then the generated report is stored under this name. You can also define the fields that you want to be displayed on the report.

To create an Inventory on-hand report storage report, perform the following steps.

- In Inventory management > Inquiries and reports > On-hand reports > Inventory on-hand report storage, select New.

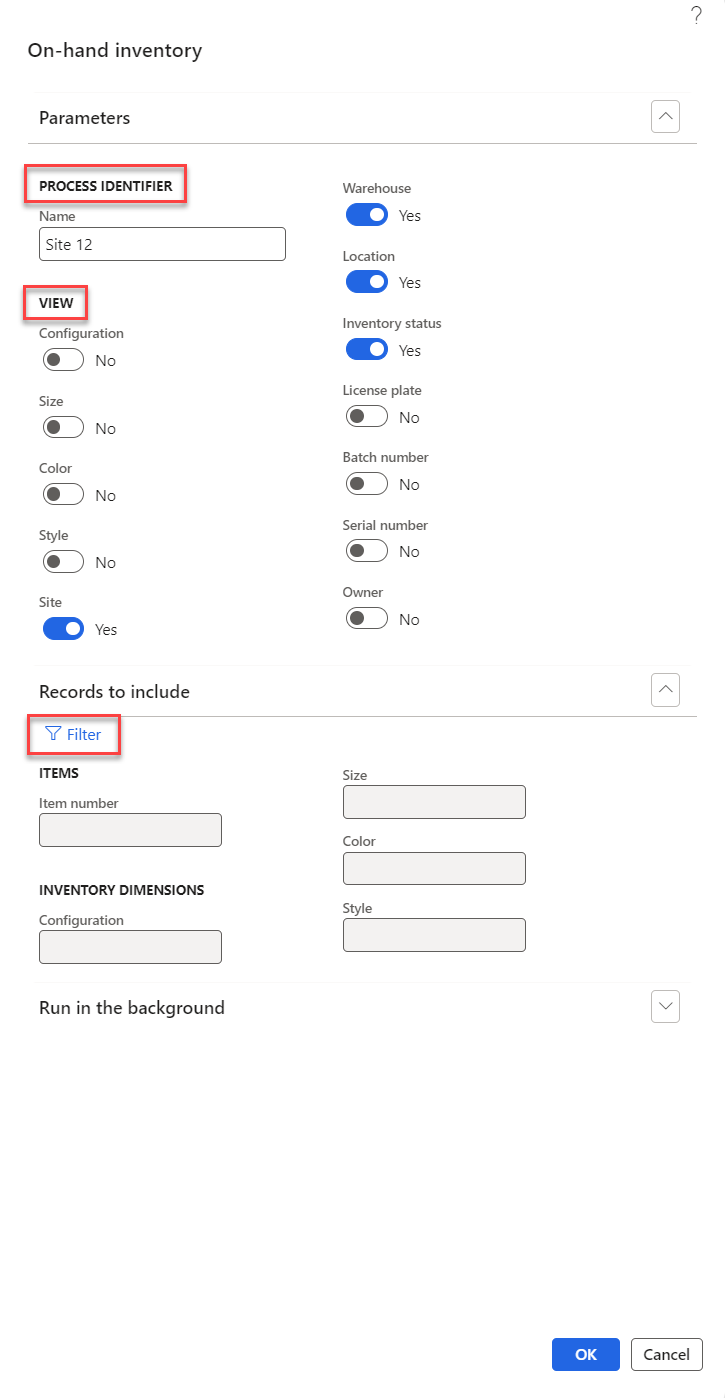

- In the Parameters FastTab in the Process identifier section, give the report a unique name in the Name field.

- In the View section, toggle all fields you want to display on the report to Yes.

- In the Records to include FastTab, you can add more search criteria by selecting the Filter icon.

- Select OK.

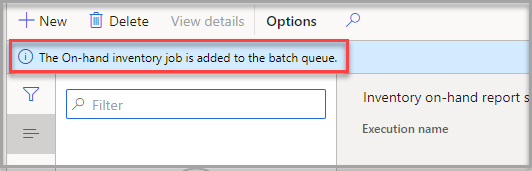

- A message appears stating that the report is added to the batch queue, which means that the report runs in the background.

- When the batch job is finished, you see the report on the Inventory on-hand report storage page, with the option to select View details of the report.

The Inventory on-hand report storage feature eliminates the need for running multiple on-hand inventory reports for the same period. The Inventory on-hand report storage reports are stored in a new data entity, enabling you to export the output of any specific, named inventory on-hand report to any format supported by data management.

Available-to-promise for the Inventory Visibility Add-in

Not only can you use the report storage feature, but there is Available-to-promise functionality for the Inventory Visibility Add-in that can increase your order fulfillment by providing visibility into future stock levels and the next available date for orders. It reduces the risk of sales opportunities and overstocking inventory, as well as insight into foreseen potential stock disruptions and the opportunity to act against it.

You can recalculate inventory based on a specified date and period to check inventory, ask for the next available dates for products, and select a recalculation period when querying the inventory on hand. You can check this availability when reserving or allocating products. When you submit a recalculation date or a query, the system performs an instance check and recalculates the latest inventory changes for the most accurate view. It supports up to seven days of rolling calculations and updates of inventory data.

In order to avoid overselling or overconsumption, you can make and track soft reservation requests against allocated inventory. Since you cannot make an additional soft reservation request against a piece of inventory, you can avoid situations where you over-allocate inventory. You can also easily compare your soft-reserved quantities against the remainder of your inventory pools. Doing so will give you an idea of the amount of inventory reserved, so you will be able to adjust your allocations accordingly.

Inventory Visibility on-hand query to support advanced warehouse management items

In addition to the inventory on-hand report, in some cases you may be using advanced warehouse management (WHS) in your environment. In this case, you would want to use the Inventory Visibility Add-In to make near real-time inventory on-hand queries of all warehouse items.

Inventory Visibility feature also stores on-hand inventory details that are filtered based on configurable business criteria so you can specify the most relevant information your company needs. The filtered on-hand inventory lists are stored locally, so they support quick access, on-demand data exports, and streamlined integration with external systems.

For example, suppose you have a warehouse item stored at Location A under warehouse 1, where warehouse management is enabled. The sales order is created, the quantity of one item is reserved for the order, and then it’s released to the warehouse. Then you reserved a quantity of one more item at a WMS location for the sales order pick work. In this case, the inventory of reserved warehouse-enabled items will be calculated as well as for the non-warehouse items.

For more information about Inventory Visibility features, see Inventory Visibility support for WMS items.