Business Central manufacturing capabilities

Premium licensing empowers you and your organization with manufacturing capabilities. Before you can begin to produce items, you must set up various parameters such as work centers, routings, and production BOMs.

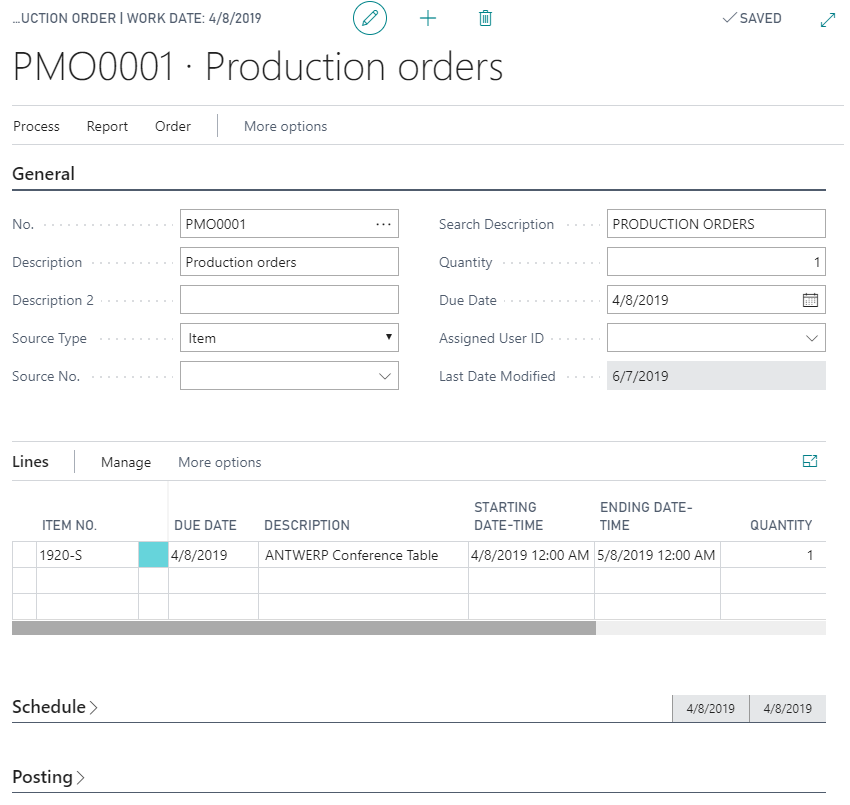

Production orders

After demand has been planned for and the materials have been issued according to production BOMs, then the actual production operations can start and be run in the sequence that the production order routing has defined.

Production orders are used to manage the conversion of purchased materials into manufactured items. Production orders route work through various work or machine centers on the shop floor.

Production orders are the central components of the program's manufacturing functionality and they contain the following information:

Products that are planned for manufacturing

Materials that are required for the planned production orders

Products that have just been manufactured

Materials that have already been selected

Products that have been manufactured in the past

Materials that were used in previous manufacturing operations

Production orders are the starting points for:

Planning future manufacturing.

Controlling current manufacturing.

Tracking of finished manufacturing.

Production orders can be created on an order-by-order basis either manually from the Production Order page or generated from the Sales Order Planning or Order Planning pages.

An important part of implementing production is to post production output to report progress and to update inventory with the finished items. Output posting can be done manually by filling and posting journal lines after production operations. Alternatively, you can perform output posting automatically with the use of backward flushing. In that case, material consumption is automatically posted along with output when the production order status changes to finished.

You can also use the Production Journal page to post consumption and output for one production order line.

Version management

Version management allows you to create and manage different versions of the manufacturing bill of materials and routings.

Agile manufacturing

With agile manufacturing, you can plan rush hours, make exceptions, and handle last-minute changes to your processes with multiple planning options.

Basic supply planning

Basic supply planning allows you to plan for material requirements based on demand with support for master production scheduling and materials requirements planning.

Demand forecasting

With demand forecasting, you can plan and create production and purchase orders, taking into consideration the demand forecast together with the level of available inventory and parameters of requirement planning.