Discover supply chain management capabilities

With Business Central, you can streamline your supply chain. You can use a wide range of sales and purchase documents to set up the sales or purchase process that best suits your needs. You can manage sales/purchase orders, blanket sales/purchase orders, and sales/purchase order processes in Business Central. You can also simply create an invoice without an order process.

Sales orders

Typically, you would use sales orders if your sales process requires that you ship parts of an order quantity, for example, because the full quantity isn't available at once. Additionally, you can use sales orders if you sell items by delivering directly from your vendor to your customer as a drop shipment. With sales orders, you can also use the order promising functionality to communicate certain delivery dates to your customers.

You can also start the sales process by first creating a sales quote, which you can convert to a sales invoice or sales order when you and the customer agree on the sale. After the customer has confirmed the agreement, you can send an order confirmation to record your obligation to deliver the products as agreed.

Special prices and discounts

You can market to your customers and customer groups with special prices and discounts. Special prices and line discounts can depend on conditions, such as the minimum order quantity and the order date. The program automatically applies the best price and the highest discount for the customer, but from your sales document, you have direct access to all possible prices and discounts. Other than the line discount, you can also set up an invoice discount. In an invoice discount, you link the discount percentage to the document amount.

Purchase orders

Typically, you would use purchase orders if your purchasing process requires that you record partial receipts of an order quantity, for example, because the full quantity was not available at the vendor. Additionally, you can use purchase orders if you sell items by delivering directly from your vendor to your customer as a drop shipment.

Business Central can monitor and control your purchase process through automated workflows, including OCR functionality. You can create replenishment orders from inventory notifications or forecasts and apply prices and discounts based on specific conditions that you agree with your vendor, such as the minimum quantity and the order date. To stay in control of purchase costs and expenses, you can even implement advanced workflow and approval structures.

Inventory, non-inventory, and services

Products can be inventory items, non-inventory, and services. Inventory items are physical inventory units, whereas non-inventory items are physical units that aren't tracked in inventory. Items that are of the services type are used as labor time units.

Categories and attributes

To increase your overview of items and to help you find them, you can categorize items and give them attributes to search and sort by.

Item availability

Inventory increases and decreases are recorded when you post purchase and sales documents, respectively. You can also increase or decrease the quantity of an item in inventory by posting directly to the item ledger entries, for example, after a physical count or if you don't record purchases. Transfers between locations change inventory quantities across your company's warehouses.

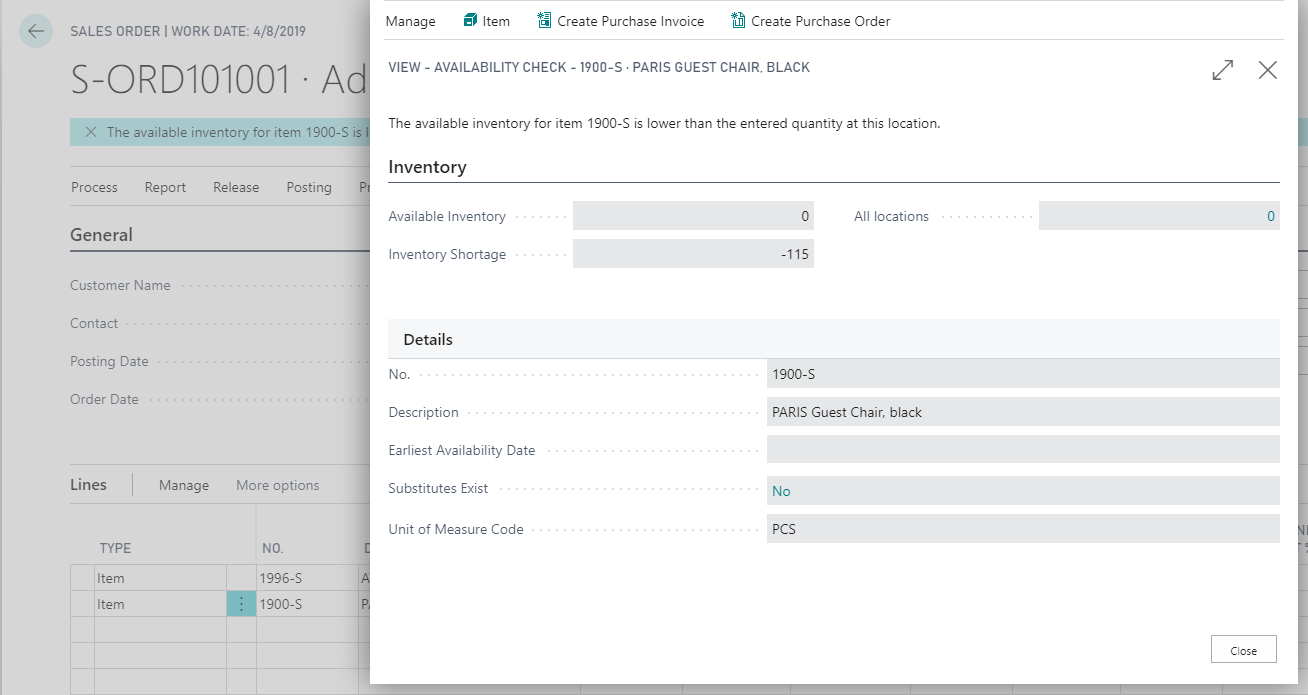

When selling items, you need to get a detailed view of an item's availability while considering the location and the date. Business Central informs you about stock shortage when you process sales so that appropriate action can be taken, such as creating a replenishment order or offering a substitute item.

Catalog items

In Business Central, you can set up and use items that you don't maintain in inventory to your customers. You can register these items that you don't want to manage in your system until you start selling them as catalog items.

When you want to start managing such items in your system, you can convert them to normal item cards in two ways:

From a catalog item card, create a new item card based on a template.

From a sales order line of type Item with an empty No. field, select a catalog item by selecting Line > Functions > Select Catalog Items. An item card is then automatically created for the catalog item.

To create a catalog item, you only need to enter a few fields. A catalog item will contain all the information that you need to send your customer a price list of items that you don't keep in stock. A catalog item typically has the item number of the vendor who supplies it. After you have entered a catalog item in a sales document, the program automatically creates a new item by using the item template on the catalog item card. The item template contains all the mandatory fields that you need to set up a regular item.

Catalog items aren't to be mistaken with non-inventory items, which are regular items that are given the type of Non-Inventory to keep them out of availability and costing calculations, for example, because they are only used internally and have a low cost.

Item substitutions

Business Central allows you to offer substitute items when requested items are unavailable. By setting up item substitutions, you can link similar items. When the program notifies you that an item that a customer has requested is out of stock, you can view the substitute items and select one that you have in stock.

Locations

You can manage inventory in multiple locations that might represent a production plant, distribution center, warehouse, showroom, retail outlet, or service car.

You can use locations with or without warehouse management functionality. If you use it without, you can track inventory by location. By setting up warehouse management functionality, you can enable warehouse documents, like put-aways and picks, and use bins.

Item transfers

With transfer orders, you can transfer items from one location to another. When transfers take more than one day, you can use in-transit locations that hold items in transfer. With direct transfers, you can transfer items without using in-transit locations. This is useful when transfer shipments and transfer receipts are processed at the same day.

Sales and inventory forecasting

The sales and inventory forecast produces, with machine learning technology, a predictive analysis of future sales and inventory levels. By setting period type and origin, you can specify the historical data that the program uses. When the inventory level drops below zero, you can create a replenishment invoice from the forecast chart.

Warehousing

With Business Central, you can receive and ship goods from the warehouse. Additionally, you can organize your internal warehouse activities, for example, if you need to put away items or move items inside or between warehouses. You can pick items for assembly, production, or shipment. You can manage items on a bin level, pick and put away items in a bin, and move items between bins by using a report that optimizes space usage and picking processes. Assembly of items for sales or inventory is also included in warehouse activities.